Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations cowski on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pipe support requirements to precast concrete tees - limitations 1

- Thread starter BossDoss

- Start date

- Status

- Not open for further replies.

Check into Red Head, Powers, Hilti, Simpson among others. They all provide a variety of fasteners to concrete.

Fastening to double tees, you will need to be aware of edge distances.

Much will depend upon the magnitude of load imposed from the conduit.

Can you be more specific?

Fastening to double tees, you will need to be aware of edge distances.

Much will depend upon the magnitude of load imposed from the conduit.

Can you be more specific?

Keep an eye on accidentally hitting prestressing tendons with your anchor.

I like to debate structural engineering theory -- a lot. If I challenge you on something, know that I'm doing so because I respect your opinion enough to either change it or adopt it.

I like to debate structural engineering theory -- a lot. If I challenge you on something, know that I'm doing so because I respect your opinion enough to either change it or adopt it.

- Thread starter

- #4

1) use anchors shallow enough that it doesn't matter.

2) fasten to the flange where there should be no prestressing.

3) Have reinforcement scans performed to locate conflicts.

I believe that most TT's have straight tendon reinforcing located in the bottom half of the stem so you should be pretty safe in the top of the stem. I can't guarantee that however.

Members TME, Precast78, and Brad805 are all precast rock stars. Hopefully one of them will make an appearance.

If you have access to the shop drawings or precaster, that would be great.

I like to debate structural engineering theory -- a lot. If I challenge you on something, know that I'm doing so because I respect your opinion enough to either change it or adopt it.

2) fasten to the flange where there should be no prestressing.

3) Have reinforcement scans performed to locate conflicts.

I believe that most TT's have straight tendon reinforcing located in the bottom half of the stem so you should be pretty safe in the top of the stem. I can't guarantee that however.

Members TME, Precast78, and Brad805 are all precast rock stars. Hopefully one of them will make an appearance.

If you have access to the shop drawings or precaster, that would be great.

I like to debate structural engineering theory -- a lot. If I challenge you on something, know that I'm doing so because I respect your opinion enough to either change it or adopt it.

TehMightyEngineer

Structural

*Poof* I have been summoned!

Most precasters use the most minimal cover allowed because it's fairly easy to keep a tight tolerance on the clear cover in the forms. Thus, I wouldn't count on KootK's option #1.

Getting anything into the vertical stem of the tee's without scanning to find gaps between strands will be hard. Even then I'd avoid going into the bottom of the stems at all costs. You may find room on the sides of the stem but I'd only use this as a last resort.

Going into the flanges will be much easier and I'd go that route. Should have a lot less rebar as well. As it's an existing structure I'd scan a section of it and try to establish what the rebar spacing is in the flanges. You should then be able to locate your pipe/conduit hanger center to center spacing so that you don't hit any bars. If you do hit a bar then I'd just patch the hole with a repair mortar like SikaTop 123 PLUS and relocate the support to miss.

I'd look at screw anchors first as they're relatively easy to install in large quantities and work well for overhead applications. As BSVBD said, Simpson, Powers, Hilti, and many more offer good products. They have free software to design most of their anchors. Power's is my preferred choice but Simpson and Hilti are good, too. I'd probably leave it up to the contractor to choose the anchor supplier and you confirm it meets your loads. If you're anchoring in the flange you probably won't have an edge distance issue but the limited thickness might cause some headaches.

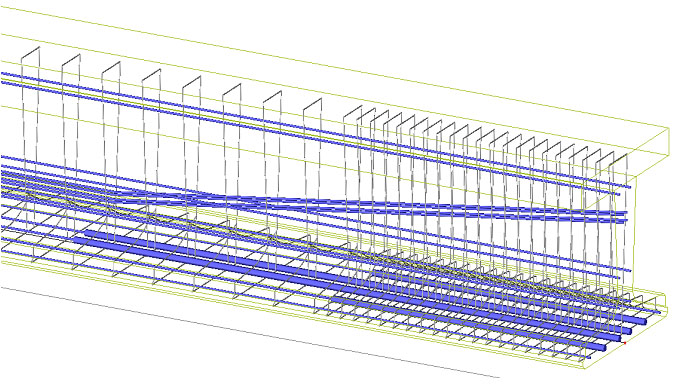

Here's a good image of the rebar in a typical double tee:

I'd avoid the areas in red where the strands are.

As far as overloading the panel I wouldn't worry too much of that, that allowance for pipes and ducts should be built into the live load requirements when they designed the building. What size pipe/conduit are we talking about?

Professional and Structural Engineer (ME, NH)

American Concrete Industries

Most precasters use the most minimal cover allowed because it's fairly easy to keep a tight tolerance on the clear cover in the forms. Thus, I wouldn't count on KootK's option #1.

Getting anything into the vertical stem of the tee's without scanning to find gaps between strands will be hard. Even then I'd avoid going into the bottom of the stems at all costs. You may find room on the sides of the stem but I'd only use this as a last resort.

Going into the flanges will be much easier and I'd go that route. Should have a lot less rebar as well. As it's an existing structure I'd scan a section of it and try to establish what the rebar spacing is in the flanges. You should then be able to locate your pipe/conduit hanger center to center spacing so that you don't hit any bars. If you do hit a bar then I'd just patch the hole with a repair mortar like SikaTop 123 PLUS and relocate the support to miss.

I'd look at screw anchors first as they're relatively easy to install in large quantities and work well for overhead applications. As BSVBD said, Simpson, Powers, Hilti, and many more offer good products. They have free software to design most of their anchors. Power's is my preferred choice but Simpson and Hilti are good, too. I'd probably leave it up to the contractor to choose the anchor supplier and you confirm it meets your loads. If you're anchoring in the flange you probably won't have an edge distance issue but the limited thickness might cause some headaches.

Here's a good image of the rebar in a typical double tee:

I'd avoid the areas in red where the strands are.

As far as overloading the panel I wouldn't worry too much of that, that allowance for pipes and ducts should be built into the live load requirements when they designed the building. What size pipe/conduit are we talking about?

Professional and Structural Engineer (ME, NH)

American Concrete Industries

TME said:*Poof* I have been summoned!

You're more responsive than most of the folks that I have on staff. Check's in the mail.

Regarding the harped strands, how common is that? Every TT? Just the long-span ones?

TME said:Most precasters use the most minimal cover allowed because it's fairly easy to keep a tight tolerance on the clear cover in the forms.

Cover would be the same as for beams right? So 1.5" minimum cover? Stirrups are not always present though?

BSBVD said:But, how would you be assured of avoiding that even in precast plank?

I think that they're pretty reliably beneath the "web" which can be located by sounding. TME to verify.

I like to debate structural engineering theory -- a lot. If I challenge you on something, know that I'm doing so because I respect your opinion enough to either change it or adopt it.

-

1

- #9

TehMightyEngineer

Structural

KootK said:You're more responsive than most of the folks that I have on staff. Check's in the mail.

If you put precast in the title of a topic on here I'll find it sooner or later.

KootK said:Regarding the harped strands, how common is that? Every TT? Just the long-span ones?

You've actually got me there as I'll admit we don't produce prestressed tee or double tee panels right now so I have limited personal experience with them. I'm trying to get our company into that market but our prestressing bed is pretty much constantly booked for our bridge deck panel work. My understanding is harped strands wouldn't be very common except on long spans like you indicated.

KootK said:Cover would be the same as for beams right? So 1.5" minimum cover? Stirrups are not always present though?

I know you're in Canada so it might be different up there. Per ACI 318 for slabs, joists, and walls I can get down to 5/8" clear cover for most bars and 3/4" clear cover for the strands. As a practical nature I try to limit things to 1" minimum as that's the smallest spacing wheel size we keep on stock.

I'd expect some sort of shear reinforcement, either a single layer of vertical welded wire reinforcement or stirrups for a wider stem. But, yes, this really depends on a lot of things. Most precasters will be using a high strength mix so often the shear can be taken with just the concrete alone.

KootK said:I think that they're pretty reliably beneath the "web" which can be located by sounding. TME to verify.

I don't see you putting them anywhere else in the form other than below the "webs". You could actually anchor between the webs using an anchor designed for hollow concrete block like this one: [URL unfurl="true"]http://www.mscdirect.com/product/details/68012244[/url]

Professional and Structural Engineer (ME, NH)

American Concrete Industries

TehMightyEngineer

Structural

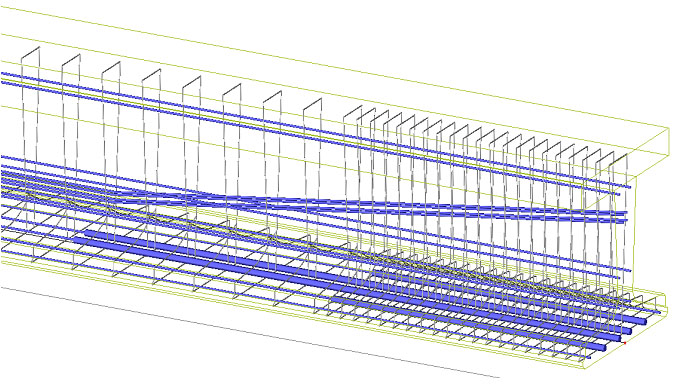

BossDoss, since you might not be familiar with the terms, harped strands are prestressing strands that are "bent" to go diagonally through the precast sections as shown below:

Most precasters will avoid doing anything like that where possible as it's time consuming.

Professional and Structural Engineer (ME, NH)

American Concrete Industries

Most precasters will avoid doing anything like that where possible as it's time consuming.

Professional and Structural Engineer (ME, NH)

American Concrete Industries

TME said:As a practical nature I try to limit things to 1" minimum as that's the smallest spacing wheel size we keep on stock.

Can you elaborate on what a spacing wheel is and how it affects cover?

I like to debate structural engineering theory -- a lot. If I challenge you on something, know that I'm doing so because I respect your opinion enough to either change it or adopt it.

TehMightyEngineer

Structural

KootK said:Can you elaborate on what a spacing wheel is and how it affects cover?

Here you go. I've don't see them used much outside of precast but they're quite nice. They automatically ensure proper clear cover all around the bar when you close the forms. Makes inspecting easy as you simply check to make sure they used the right wheels on the cage. We use them on both vertical and horizontal surfaces.

Professional and Structural Engineer (ME, NH)

American Concrete Industries

TehMightyEngineer

Structural

It's funny, went out drinking last night with some coworkers and the bar had precast double tee beams with pipes and electrical conduits hanging off the tees.

I should have taken a picture but didn't think to at the time. It was all fire suppression and small conduit for romex cables for lighting and they were attached with what appeared to be short masonry screws. Many were attached into the bottom of the stem (but again I don't recommend this).

Professional and Structural Engineer (ME, NH)

American Concrete Industries

I should have taken a picture but didn't think to at the time. It was all fire suppression and small conduit for romex cables for lighting and they were attached with what appeared to be short masonry screws. Many were attached into the bottom of the stem (but again I don't recommend this).

Professional and Structural Engineer (ME, NH)

American Concrete Industries

- Status

- Not open for further replies.

Similar threads

- Question

- Replies

- 3

- Views

- 11K

- Replies

- 3

- Views

- 591

- Replies

- 5

- Views

- 2K

- Locked

- Question

- Replies

- 7

- Views

- 4K

- Question

- Replies

- 2

- Views

- 718