EngDM

Structural

- Aug 10, 2021

- 706

Hey all,

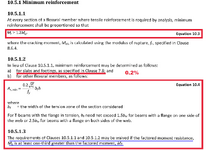

I'm just wondering if CSA minimum steel for flexural members, clause 10.5.1.2 requires the reinforcing steel to be in the tension zone. The clause doesn't appear to indicate that it HAS to be tension steel (though obviously this is ideal); when using Jabacus today I noticed that their min steel check was based on the steel in the tension zone only.

I was under the impression that so long as the tension steel is designed for the loading, that the min steel was for the gross cross sectional area. Hopefully someone can confirm or point me somewhere that outlines it a bit more clearly.

I'm just wondering if CSA minimum steel for flexural members, clause 10.5.1.2 requires the reinforcing steel to be in the tension zone. The clause doesn't appear to indicate that it HAS to be tension steel (though obviously this is ideal); when using Jabacus today I noticed that their min steel check was based on the steel in the tension zone only.

I was under the impression that so long as the tension steel is designed for the loading, that the min steel was for the gross cross sectional area. Hopefully someone can confirm or point me somewhere that outlines it a bit more clearly.