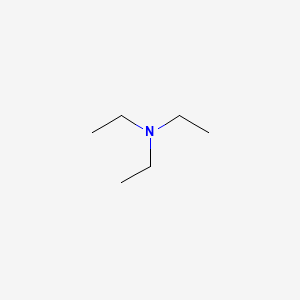

rika kose

Chemical

- Jun 11, 2019

- 68

someone is familiar with TMA anhydrous?

Is liquid TMA conductive? if it is not, we have to be careful about the transportation for its static electricity. it is flammable.

Thanks.

Is liquid TMA conductive? if it is not, we have to be careful about the transportation for its static electricity. it is flammable.

Thanks.