abdallah hamdan

Structural

- Oct 13, 2021

- 36

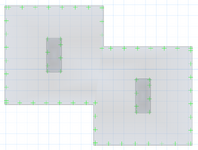

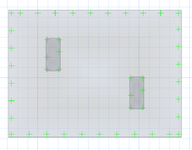

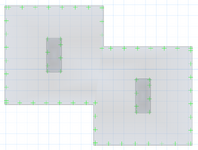

I was designing a Combined Footing for columns that are close to each other, and the columns are not at the same horizontal and vertical level, as shown

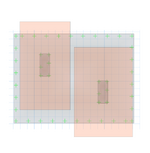

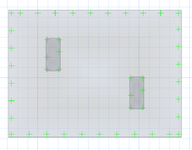

When I studied another appropriate shapes for the foundation, I found that the following shape require less area and smaller thickness , 65 cm instead of 75 cm. i have not seen this shape in the footings before , Is this shape acceptable and practical?

When I studied another appropriate shapes for the foundation, I found that the following shape require less area and smaller thickness , 65 cm instead of 75 cm. i have not seen this shape in the footings before , Is this shape acceptable and practical?