Just to pile on, you seem to be approaching this with an unyielding bias toward believing this is a big problem, yet it is NOT.

Motor electrical energy consumption is a factor of two things: The

connected shaft load and the

efficiency of converting the electrical energy into kinetic energy. You already know that your connected shaft load is lower, how much lower is actually irrelevant in that if it is 200kW, it is 200kW regardless of the size of the motor. then as a gross rule, motor efficiency is the only real issue here.

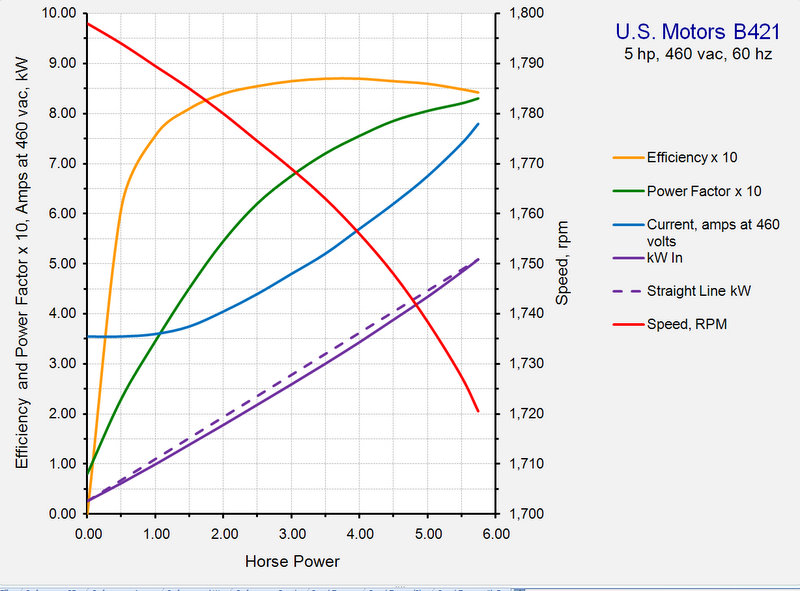

Motor efficiency peaks well below full loading and in small motors, drops again a tiny amount at above about 95% loading. The chart below is very typical for a small motor:

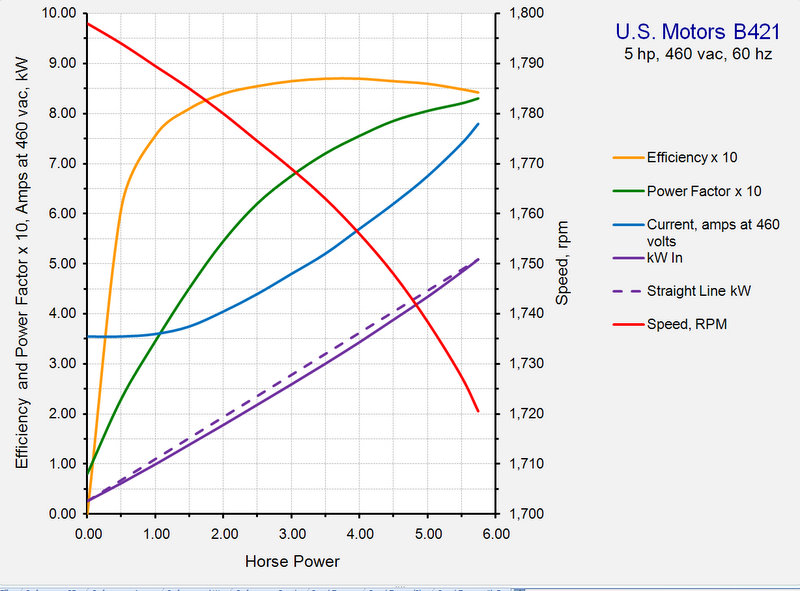

But as the motor size goes up, inherent design issues in the way they must be built lead to better efficiency, so the peak happens at much lower levels and stays higher throughout. This chart illustrates that as a comparison based on size:

That is why we are telling you that you have little, if anything, to gain by thinking that just because your motor is not fully loaded, it is consuming more energy. It might be, but it is a very small amount at worst, and the RISKS associated with UNDERSIZING the motor are worse, therefor not always worth the effort. For example if the original mill designer KNEW, from his specific experience AS a mill designer, that there was a "worst case scenario" which might require a very brief peak torque requirement from that motor, that would likely be the reason he chose a 250HP motor. But if you do NOT know about that, then a smaller motor may create a situation wherein the mill stalls and production is lost. That lost production has a very direct economic effect, usually MUCH greater than any perceived energy savings you might have realized.

"Will work for (the memory of) salami"