XR250

Structural

- Jan 30, 2013

- 5,556

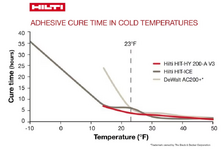

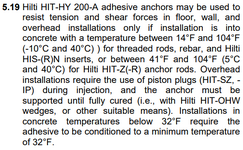

Seems like the Acrylic based systems have a wider range of substrate install temps than the Epoxies do. I never knew this. Do any of you specify different systems in the Winter versus Summer? The Simpson rep informed me the lumber yards are supposed to educate the contractors on this and sell them the appropriate product. (this seems doubtful)

I asked a few contractors and they have never heard of this. Granted, in my area (central NC USA) winter is not that harsh so maybe it is not an actual issue.

I asked a few contractors and they have never heard of this. Granted, in my area (central NC USA) winter is not that harsh so maybe it is not an actual issue.