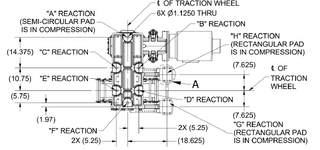

I am looking for some help with design of anchorage for a basement elevator machine replacement. The current machine has (4) 3/4 anchor bolts, and not in the correct locations for the new machine. New design loading will be approximately 26k sustained tension load on the anchor bolt group. Attached photo of 1 of 4 ABs and the machine overall (couldn't figure out how to rotate the images - sorry). I also attached an example bolt group layout from one particular machine, not necessarily the machine that will be used here - the manufacturer specifies that bolt F should be designed for 60% of total load - or ~15.6k tension, this is the most critical bolt. Option A would be to install anchor bolts in the locations A-F to directly handle the loads, Option B would be to install anchors in different locations and add some grillage assembly to which the machine will be mounted. Option A if preferable because it doesn't require additional steel, and doesn't add to the height of the new machine.

View attachment IMG_6400.jpg

I have extensive experience in elevator design, and specifically basement elevator design. For new construction this is easy, even for most modernizations it is straightforward to reuse the existing anchors, but this will be new anchors in existing concrete, so definitely not my forte. Right now I am looking for conceptual help, not free design. When the time comes I'll need a stamped anchorage design (NY) that I can use and I will be more than happy to pay for. TYIA

View attachment IMG_6400.jpg

I have extensive experience in elevator design, and specifically basement elevator design. For new construction this is easy, even for most modernizations it is straightforward to reuse the existing anchors, but this will be new anchors in existing concrete, so definitely not my forte. Right now I am looking for conceptual help, not free design. When the time comes I'll need a stamped anchorage design (NY) that I can use and I will be more than happy to pay for. TYIA