TRAK.Structural

Structural

- Dec 27, 2023

- 292

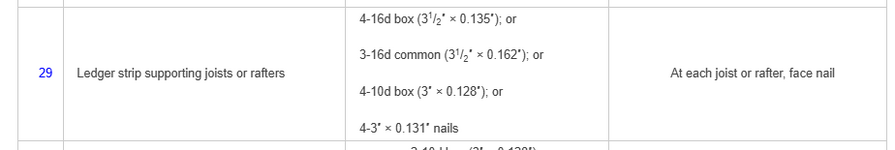

So a contractor I do work with from time to time called me out to look at something. The inspector failed his floor framing because he over-notched the joists due to an existing 2x4 ledger strip (dark colored wood) rather than the typical 2x2 strip (it's a renovation job). So now I'm trying to rationalize if/how I can make this work. My first thought is to just have them put hangers on each joist and nail them to the 2x4 ledger strip, but this 2x4 is only face mounted to the rim/band behind it with no vertical support from below. Ideally I want most of the load being transferred directly to the band which is vertically supported by the foundation wall instead of to the 2x4 and then to the band through nail shear. Am I over thinking this? What does the group think?