rotarypower

Mechanical

Hi guys wondering if anyone knows where I can get information about the geometry of a jet pump cone for a clear water application?

I need to design a cone for a vein mounted cone off from a axial jet pump.

Can someone lead me in the right direction what profiles I can use, and basic hydrodynamic theory that will be used in such a scenario?

My instincts tells me the cone profile should match the drag profile of the center section of the vein housing, but is there any information someone can supply about theory of such a circumstance, and optimization?

A question that has also been posed, is that turbulators are not needed in a profile of this sort correct? With a cone profile (if designed correctly) there is no draft effect that should happen correct?

BTW there is a wealth of pump info here if you have not seen it yet.

Thanks to the author!

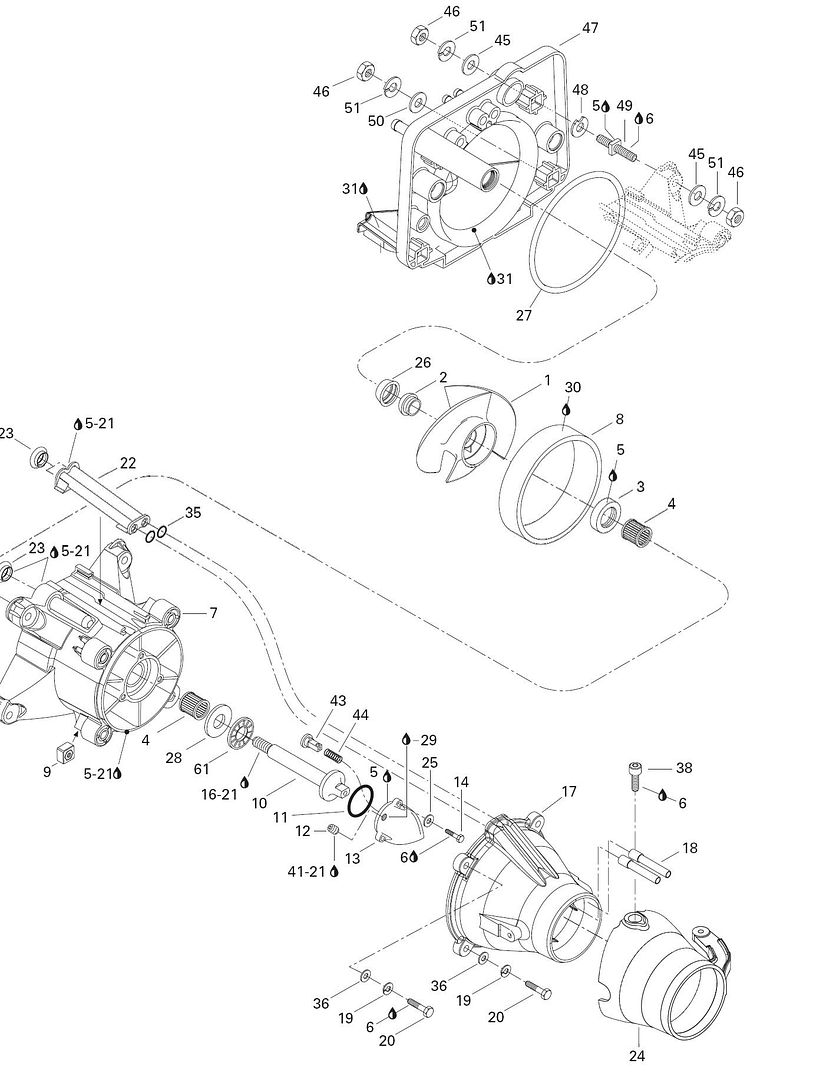

pic of pump diagram. If it does not load properly, please inform me and I will link to a site that will allow it.

I need to design a cone for a vein mounted cone off from a axial jet pump.

Can someone lead me in the right direction what profiles I can use, and basic hydrodynamic theory that will be used in such a scenario?

My instincts tells me the cone profile should match the drag profile of the center section of the vein housing, but is there any information someone can supply about theory of such a circumstance, and optimization?

A question that has also been posed, is that turbulators are not needed in a profile of this sort correct? With a cone profile (if designed correctly) there is no draft effect that should happen correct?

BTW there is a wealth of pump info here if you have not seen it yet.

Thanks to the author!

pic of pump diagram. If it does not load properly, please inform me and I will link to a site that will allow it.