megavites

Chemical

- Aug 31, 2007

- 5

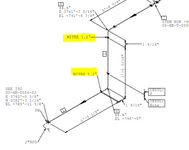

In the 3d modeling world, we need to set a deflection angle for SW fittings. Looking at B16.11, pg 7.2, myself and another arrived at a real world deflection angle of .29 degrees. This allows a very small adjustment of pipe angle at a socketweld fitting.

Now, in the past, i have seen isometrics go to a fab shop with a .5 degree deflection, with no resulting pushback from the fab shop.

What have others seen in this case?

Now, in the past, i have seen isometrics go to a fab shop with a .5 degree deflection, with no resulting pushback from the fab shop.

What have others seen in this case?