JoelTXCive

Civil/Environmental

- Jul 24, 2016

- 933

Hi there.

I am designing a screened steel gate for pump station. The gate is 8ft wide by 7ft tall (they want to drive a bobcat/small tractor into the pump station to clean the crud out after a major storm event).

95% of the time the gate will be dry, but in flood events, water will flow through the gate and into the pump station. If debris gets hung up on the gate then the gate will be subject to a significant lateral load. As of now, the hydraulics people are telling me to assume 10ft of static water head on the gate if it gets clogged up.

I'm looking for off the shelf hinges, but I think I am at the extremes of what is available. I'm looking at factored loads in the neighborhood of 2,500 to 3,000 lbs per hinge.

Maybe i can design my own piano hinge or barrel hinge?

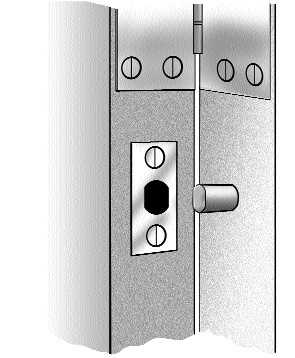

Does anyone know of some good design resources for this? I've googled, but not come across anything. (below is an example photo of what I am thinking)

Thank you.

I am designing a screened steel gate for pump station. The gate is 8ft wide by 7ft tall (they want to drive a bobcat/small tractor into the pump station to clean the crud out after a major storm event).

95% of the time the gate will be dry, but in flood events, water will flow through the gate and into the pump station. If debris gets hung up on the gate then the gate will be subject to a significant lateral load. As of now, the hydraulics people are telling me to assume 10ft of static water head on the gate if it gets clogged up.

I'm looking for off the shelf hinges, but I think I am at the extremes of what is available. I'm looking at factored loads in the neighborhood of 2,500 to 3,000 lbs per hinge.

Maybe i can design my own piano hinge or barrel hinge?

Does anyone know of some good design resources for this? I've googled, but not come across anything. (below is an example photo of what I am thinking)

Thank you.