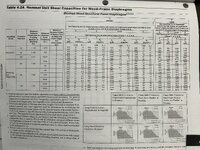

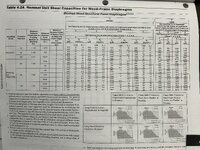

hello, can you help me understand the difference between the two nailing categories in the seismic area, (6, 4, 2.5, and 2) vs (6, 6, 4, 3). I understand that there are different cases based on the layout of the panels resting on the members, however what does "other panel edges" mean? If i had a case 1 and 3 type of layout, would I be using the 1st row or 2nd row for my nailing spacing and finding my shear capacities?

Thank you.

Thank you.