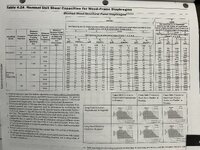

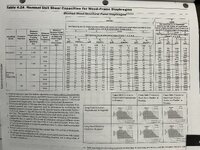

Look at the table to the left, that will tell you what row to use: based on the deck sheathing, nails, and width of the joist/truss you are nailing into.

The numbers you list are the nail spacings for the criteria listed. So for Case 3 loading, the continuous edges are parallel to the force and the other panel edges (the ones that are not continuous) are perpendicular. The spacing of those can be greater for the same strength, but what carpenter will want to have different spacings for each different edges?

For Case 1 loading, there are no continuous edges parallel to the loading, so Case 1 is not listed in the top grouping.

So if you were using 1/2" thick Structural 1 sheathing with 8d nails and 2" nominal joists, and you needed a shear of 700 plf, then you would want a nail spacing of 4" along the continuous edge, and 6" on the other edges for 720 plf. And you wouldn't need the full 1/2" thick sheathing for shear, but you'd most likely want that for out of plane loading. Does that help?