Hi Guys,

My question may start as weird and weirder as you go along, but would help get rid of the useless thoughts.

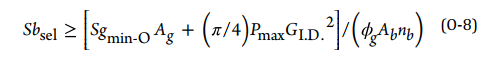

I am calculating my bolt load, and minimum pretension based on the worst case of the three cases,

1) minimum seating stress (πbGy)=Wg1

2) working condition (2πbGPw + 0.785G^2Pw)=Wg2 assuming external thermal and mechanical load as zero.

3) Hydrostatic condition (2πbGPt + 0.785G^2Pt)=Wg3

My question is when I have applied pretension based on the maximum force calculated above, let's assume the value is from point # 3 (considering it will be maximum as there is no other load considered for working condition).

When my equipment is under test conditions, there will be forces that will be generated that will be in the opposite direction of the initially created clamping force (Fc). Will my resultant forces(Fr) be

1) Fr=Fc-0.785G^2Pt or

2)Fr=Fc-(2πbGPt + 0.785G^2Pt)----(Which technically would say no clamping force is now present), how would that look as the gasket technically is not seated as per πbGy, isn't that an issue.

If point 2 is true, it means when pressure is applied to the gasket faces exposed to the fluid it will apply force opposite to clamping force.

Another question that bothered me, my pretension also keeps the bolt in tension whereas the external load (other than compressive) also should keep adding the bolt tension, would the load be added for stress calculation or the clamping force generated between joint members will take the hit?

My question may start as weird and weirder as you go along, but would help get rid of the useless thoughts.

I am calculating my bolt load, and minimum pretension based on the worst case of the three cases,

1) minimum seating stress (πbGy)=Wg1

2) working condition (2πbGPw + 0.785G^2Pw)=Wg2 assuming external thermal and mechanical load as zero.

3) Hydrostatic condition (2πbGPt + 0.785G^2Pt)=Wg3

My question is when I have applied pretension based on the maximum force calculated above, let's assume the value is from point # 3 (considering it will be maximum as there is no other load considered for working condition).

When my equipment is under test conditions, there will be forces that will be generated that will be in the opposite direction of the initially created clamping force (Fc). Will my resultant forces(Fr) be

1) Fr=Fc-0.785G^2Pt or

2)Fr=Fc-(2πbGPt + 0.785G^2Pt)----(Which technically would say no clamping force is now present), how would that look as the gasket technically is not seated as per πbGy, isn't that an issue.

If point 2 is true, it means when pressure is applied to the gasket faces exposed to the fluid it will apply force opposite to clamping force.

Another question that bothered me, my pretension also keeps the bolt in tension whereas the external load (other than compressive) also should keep adding the bolt tension, would the load be added for stress calculation or the clamping force generated between joint members will take the hit?