Hello, gentlemen!

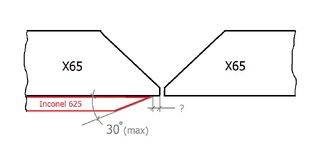

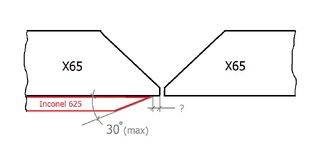

We prepare the weld qualification for butt weld of X65 pipe cladded with Inconel 625 to no cladded pipe X65. Could you, please, advise where I can find acceptable scheme for weld joint preparation (ASTM, API etc.) ? Proposed joint configuration attached (picture). Thanks in advance!

We prepare the weld qualification for butt weld of X65 pipe cladded with Inconel 625 to no cladded pipe X65. Could you, please, advise where I can find acceptable scheme for weld joint preparation (ASTM, API etc.) ? Proposed joint configuration attached (picture). Thanks in advance!