Moooo

----------------Regarding seasonal fuel mixture-------------------

“Varieties of LPG bought and sold include mixes that are primarily propane, mixes that are primarily butane, and mixes including both propane and butane, depending on the season - in winter more propane, in summer more butane.”

Wikipedia and numerous other sites

“Commercially available LPG in the USA ranges from 49-99% propane by weight.”

Southwest Research Institute; Project 03.07065 Final Report

“In the United States, the propane industry has attempted to adopt an automotive propane standard known as HD5. [min. 90% propane] The standard is not universally observed. Because, the concentration of propane as high as virtually 100 %, to as low as 50 % in certain locations. Much of the remainder of the gas is butane and some other hydrocarbons.”

West Virginia University – Alternative Fuel Vehicle Training Program; Propane Review;

“Propane is a premium product with better vapour producing qualities, but it costs more, yet contains less energy than general blend LPG.”

Rockgas Ltd.;

“But sometimes (propane) is mixed with butane, and not identified as other than propane. Coming home to northern states from AZ with a full tank of mostly butane -- which won't vaporize until it gets above 32F -- can cause a problem, since butane needs to be above freezing to vaporize. If it doesn't vaporize, your appliances won't work. If you fill up with Butane in Texas and drive home to Minnesota in winter months, you'll find none of your "propane" appliances will work.”

RVer’s Online;

(similar -

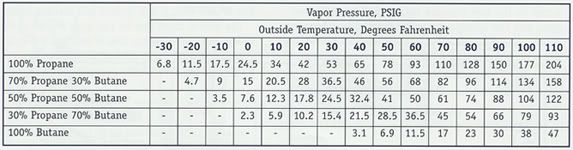

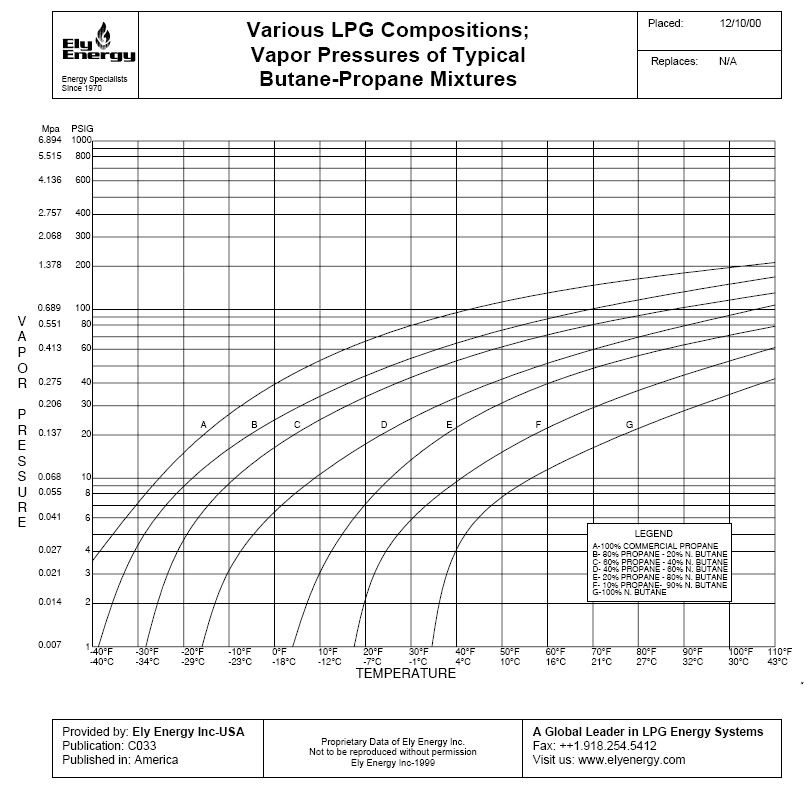

I found two different vapor pressure sets of data. Not sure why they differ, but 50/50 LPG has only ~1/3rd the pressure of pure propane at 0deg F.

vapor pressure @ 0deg F

100% propane: 38psi (or 25psi?)

50% propane, 50% butane: 10psi (or 7.6psi?)

-------------On cold temp starting issues--------------------

Ford 1999 F-250 bi-fuel is programmed not to use propane below 20deg F. No reason given.

“Engines powered by gaseous fuels are generally considered easier to start than gasoline engines in cold weather because gaseous fuels are already vaporized before inducted into engine. However, under very cold temperatures, cold-start difficulty occurs for propane. In extreme cold weather environments a supplemental electrically powered heater will likely be necessary.”

BAF Technologies; LPG 101

“Some argue that propane is a better fuel in cold climates because it does not have the low viscosity and waxing problems of diesel fuel and that spark machines are easier to start. In actual practice a diesel engine offers more reliable starting in cold weather, and in areas which have wide temperature swings diesel is also lower in maintenance. The problem with propane engines is vaporizing the liquid fuel and the load valve adjustments which are subject to temperature swings. Until a computerized propane carburetor is available, diesel is the preferred choice for reliability in cold weather.”

Polar Power, Inc.;

“Vapor injection offers better range and no difficulties with hot conditions, but cold-start emissions can be a problem if the gas liquefies in the fuel line. The liquid is much denser than the vapor, so the injectors allow much more mass of fuel into the combustion chamber than is required. This produces high CO and HC emissions.”

Center for Environmental Research and Technology - University of California, Riverside; Development of an Advanced, Low-Emitting Propane-Fueled Vehicle

“..after the engine was shut off, the fuel in the line could condense (if the vehicle was cooled to 40°F) to a liquid at 90 psi. Because the injectors were designed to pass vapor, not liquid, they would allow too much fuel into the combustion chamber during cold-starting.”

Center for Environmental Research and Technology - University of California, Riverside; Development of an Advanced, Low-Emitting Propane-Fueled Vehicle

“Propane and natural gas require from 50% to 100% higher temperature to ignite a charge as compared to gasoline. The ignition must be in good shape.”

Alternate Fuels Technologies, Inc.;

----------------Other ideas on starting on gas vs propane----------

ISZ