mountaineers19

Structural

- Jun 4, 2024

- 19

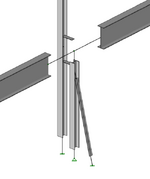

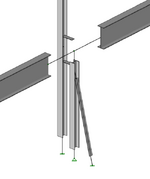

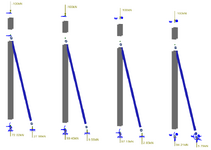

I am trying to find alternatives to increasing the capacity of this crane without messing with the foundation if I do not have to. I know the foundation is good for the current loading and according to my model this brace would handle the additional load and help disperse it on a larger effective area on the foundation. Does this seem like a logical fix or would the load just go straight down regardless?