XR250

Structural

- Jan 30, 2013

- 5,879

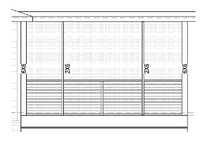

This is the wish of the Arch/Owner on a screened porch. This is the typical eave side of a gable roof. The members support a beam that supports the roof framing. The demand on the 2x6's is about 1,000 lbs. ASD. The 2x6's actually check out (with gravity loads and a 200lb horizontal point load from the guardrail) assuming they are braced weak axis by the guardrail.

They also sorta check out un-braced with just gravity loads. I am assuming everything is concentric etc. The (3)2x10 horizontal beam almost makes it strength-wise for a clear span but fails on deflection so I don't feel there is a safety issue here. Am I being too much of a Cowboy?

I can probably also use PT LVL's which are 1 3/4" thick and are significantly better. The beam will be 3 ply with 2 -layers of PT plywood so it matches the thickness of the supports to help with my concentricity. I might have other options such as using a deeper beam that does require intermediate supports or maybe a flitch beam. But for discussion sakes, what are y'all's thoughts about the 2x6's?

They also sorta check out un-braced with just gravity loads. I am assuming everything is concentric etc. The (3)2x10 horizontal beam almost makes it strength-wise for a clear span but fails on deflection so I don't feel there is a safety issue here. Am I being too much of a Cowboy?

I can probably also use PT LVL's which are 1 3/4" thick and are significantly better. The beam will be 3 ply with 2 -layers of PT plywood so it matches the thickness of the supports to help with my concentricity. I might have other options such as using a deeper beam that does require intermediate supports or maybe a flitch beam. But for discussion sakes, what are y'all's thoughts about the 2x6's?