JStructsteel

Structural

- Aug 22, 2002

- 1,446

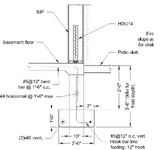

I have a 1" anchor that needs to be epoxied into a 10" thick wall for a hold down at a shear wall. I tired PROFIS and no go. Is there any literature for deep embedment with epoxies?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

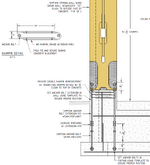

Panels are pretty much set in stone for the openings. The shear wall at this area is small, carrying alot of load.Any chance you can get the SIP panel design changed? Looking for options to use multiple smaller diameter hold downs?

I will look into this. Probably the way to go.you might be able to “lap” the anchor with the vertical wall reinforcing to preclude breakout.

Hilti has a technical guide with examples for this situation. They also have a free software for this.

Good luck. Unless you can drill down and epoxy to the footing, I doubt you'll be anywhere close to the capacity you need.I think I will have to get with Hilti and see if they have any recommendations for a deep embedment.

Have you come across a reference that goes over the breakout cone for epoxied anchors? I was under the impression that if your adhesive worked, then your forces transfer to the surrounding concrete. Is the issue that the tension is resisted along the anchors length, whereas headed anchors are held down at the end of the anchor by concrete in compression?"Lapping" with rebar is similar to what I referenced above (anchor reinforcement). The "codified" method is for headed studs with a breakout cone and should not be aplied directly to epoxied anchors without some thought. The mechanism is a bit different. I would not be surprised if Hilti had a technical guide that applies a similar approach to epoxied bars. I think there is some logic to treating epoxied bars similar to developing rebar, but I have not seen a ton of guidance on this. Ideally the anchor is fairly close to existing dowels, otherwise this might be difficult to make work (think non-contact splices).

If you have a hard time getting it to work out, you might look at the "concrete chunk" I sketched above as a backup plan. If you could get the wall and concrete chunks to act together you might be able to effectively control concrete breakout and use traditional eopxy embedment calculations. Just a thought.

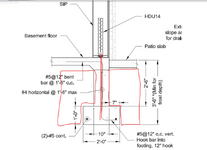

It's likely there is a compression load nearby to offset it so he would only have to look at the foundation as a beam instead of dead weight.Yikes - It sounds like they put you into a pretty tough spot. It is going to take quite a bit of footing/wall/slab to resist 11.4k of force, especially if you are trying to use 0.6D..

Maybe you can add concrete to each side wall here that encompasses the wall pour, adds some ballast to resist the uplift force, and restrains the breakout a bit. It may take a decent chunk of concrete, but might be the easiest solution.