It seems I'm always posting about deflection track on here. So, here's another simple question:

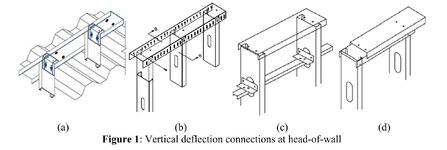

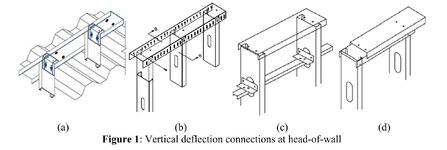

When do you specify deflection track in your design? Either slotted deflection track, nested deflection track, or single deep leg track with no attachment to the stud.

Do any of the following factors affect your decisions on a project-to-project basis:

When I showed up, the 25-gauge studs were screwed to the edge of the standard 25-gauge track...completely different than my design. I talked with the framer and his reply was basically "...we've never had to use anything but standard track, even in high snow load areas...". I called a colleague who only suggested that there is some old building standard that says deflection track isn't required for walls over 12'-0". It was a nugget of information passed down from an old-timer we both worked with before. I couldn't find this reference. My fix is to unscrew the studs (the screw location already fouls edge distances), add 3"x3"x20ga angles either side of the existing track, and add a bridging channel within 18" of the top of wall. It seems easier than replacing all the tracks, but that is also an option.

I'm wondering if I'm being overly conservative specifying deflection track everywhere. This is now the second time where the contractor has royally screwed (pun intended) it up. I would really appreciate hearing how others approach this design or if there are any nuggets in a reference that defines when/where deflection track is needed.

When do you specify deflection track in your design? Either slotted deflection track, nested deflection track, or single deep leg track with no attachment to the stud.

Do any of the following factors affect your decisions on a project-to-project basis:

- Does the roof framing (wood decking, steel decking w/ OWSJ, concrete slab) make a difference to you? Perhaps certain framing arrangements are more susceptible to deflection.

- Does the age of the structure make a difference to you? Perhaps long-term creep or deflection has already set-in and you expect the deflection to be not as critical.

- Does the gauge of the studs make a difference to you? Perhaps 25-gauge studs would require deflection track because they are not able to resist axial compression compared to 20-gauge or 18-gauge studs.

- Does the height of the partition wall make a difference to you? Perhaps a wall over 12'-0" requires deflection track and walls under that (or another) threshold height don't.

- If the wall is not sheathed full-height (e.g. drywall stops at drop ceiling), is there less concern of damage if no deflection track is used?

- Do the number of storeys in a building affect your decision?

When I showed up, the 25-gauge studs were screwed to the edge of the standard 25-gauge track...completely different than my design. I talked with the framer and his reply was basically "...we've never had to use anything but standard track, even in high snow load areas...". I called a colleague who only suggested that there is some old building standard that says deflection track isn't required for walls over 12'-0". It was a nugget of information passed down from an old-timer we both worked with before. I couldn't find this reference. My fix is to unscrew the studs (the screw location already fouls edge distances), add 3"x3"x20ga angles either side of the existing track, and add a bridging channel within 18" of the top of wall. It seems easier than replacing all the tracks, but that is also an option.

I'm wondering if I'm being overly conservative specifying deflection track everywhere. This is now the second time where the contractor has royally screwed (pun intended) it up. I would really appreciate hearing how others approach this design or if there are any nuggets in a reference that defines when/where deflection track is needed.