PRESIDENTJ

Structural

- Mar 21, 2024

- 10

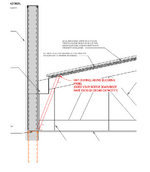

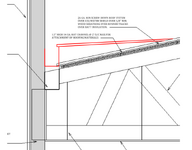

I have a light gauge structure that I am transferring roof diaphragm to the shear walls at the eaves and rakes. Both the eave and rake have a parapet situation. The eaves need an internal gutter. What's the best way to get my roof diaphragm to the light-gauge shear walls? Also, should I place a box header between each stud at the roof line?

I have included a snippet of my condition.

I have included a snippet of my condition.