Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations cowski on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Downsized charged engines, peak cylinder pressures? 5

- Thread starter HarleyE30

- Start date

- Status

- Not open for further replies.

SomptingGuy

Automotive

If you read the auto engineering rags, you'll see things like 30bar BMEP. I did read today from one powertrain design team about engine architectures capable of 140bar peak pressure. But these are all development, not production engines.

- Steve

- Steve

I've heard peak combustion pressure numbers similar to what SomptingGuy notes for current SI turbo engines. Knock is obviously an issue, but one other problem that pops up once peak combustion pressures go higher than around 2000psi is the combined thermal/mechanical stress causing fatigue failures with aluminum head materials. As the section thickness of the deck and chamber walls is increased to deal with higher pressure loads, it becomes difficult to adequately cool isolated chamber surfaces such as the narrow bridges between valve seats and the spark plug port.

Lou Scannon

Automotive

Interesting design space. Aluminum,by virtue of its high conductivity, permits higher compression ratios or otherwise more aggressive combustion recipies, from a knock margin point of view. And then the other edge of the sword is aluminum's lower fatigue performance, relative to ferrous material. Sounds like fun, for those fortunate to be playing in that sandbox.

"Schiefgehen will, was schiefgehen kann" - das Murphygesetz

"Schiefgehen will, was schiefgehen kann" - das Murphygesetz

turbocohen

Automotive

Yall might appreciate this article on the subject of BMEP.

Lou Scannon

Automotive

Interesting article & seems to have good knowledge base. The only part where I raised my eyebrows a bit was the following:

[ol 1]

[li]Who these days is developing a high performance non-turbocharged diesel engine?

[/li]

[li]Are we talking about a smokey exhaust or what? I've visualizing an exhaust plume that a squid would be proud of. [/li]

[/ol]

Does anyone know of a case in point?

"Schiefgehen will, was schiefgehen kann" - das Murphygesetz

EPI said:It is worthwhile to note that a contemporary, normally-aspirated CI (compression-ignition) engine can easily make 15 bar of BMEP.

[ol 1]

[li]Who these days is developing a high performance non-turbocharged diesel engine?

[/li]

[li]Are we talking about a smokey exhaust or what? I've visualizing an exhaust plume that a squid would be proud of. [/li]

[/ol]

Does anyone know of a case in point?

"Schiefgehen will, was schiefgehen kann" - das Murphygesetz

140Airpower

Automotive

Komodo86, when you say average pressure is "much, much higher", do you have an example?

-

1

- #10

GregLocock

Automotive

if only there was a way of working out the mean effective pressure from the max torque and capacity of the engine.

Cheers

Greg Locock

New here? Try reading these, they might help FAQ731-376

Cheers

Greg Locock

New here? Try reading these, they might help FAQ731-376

"Komodo86, when you say average pressure is "much, much higher", do you have an example?"

The fuel is always going to the limiting factor to peak pressures. With turbocharging however, it is not about peak pressure.

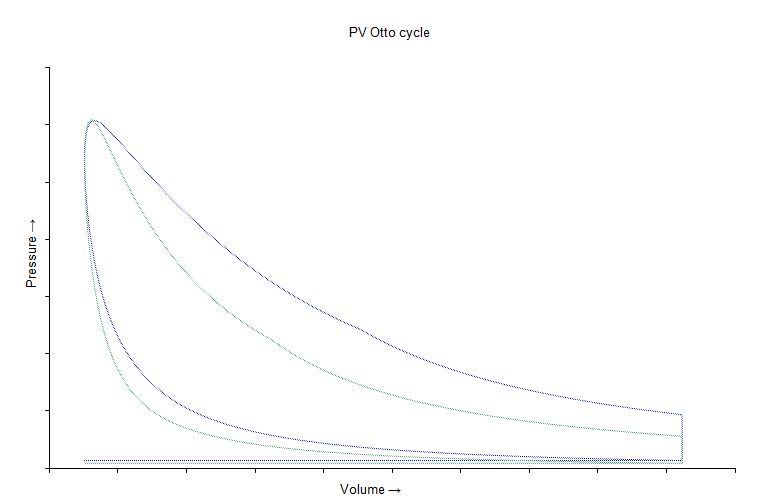

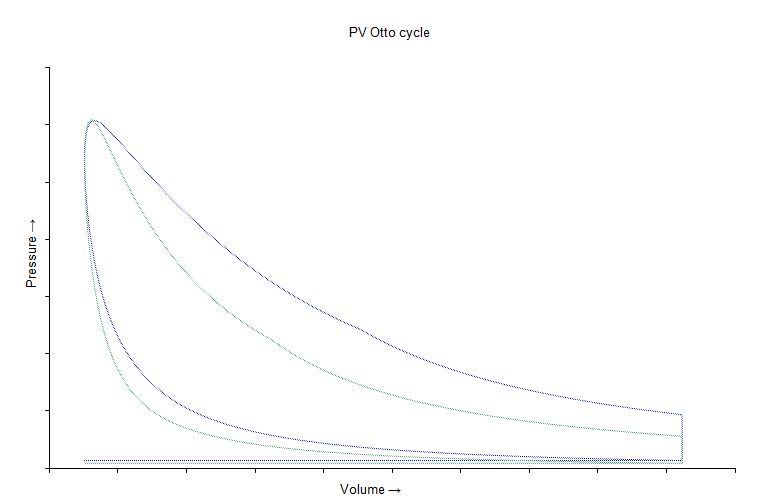

Here's a modelled Otto cycle for comparison for two engines.

The green trace is a NASP engine of 11:1 compression, with 45° ignition advance.

The blue trace is the same engine boosted to 1 bar. Ignition timing reduced to 16° so that the peak cylinder pressure remains the same as the NASP model.

The difference is quite clear. The boosted engine maintains a significant advantage in pressure throughout the power stroke, despite have no gain in peak pressure.

In reality, a boosted engine may be able to handle a small gain in peak as well, but the majority of the gain comes from average pressure.

The fuel is always going to the limiting factor to peak pressures. With turbocharging however, it is not about peak pressure.

Here's a modelled Otto cycle for comparison for two engines.

The green trace is a NASP engine of 11:1 compression, with 45° ignition advance.

The blue trace is the same engine boosted to 1 bar. Ignition timing reduced to 16° so that the peak cylinder pressure remains the same as the NASP model.

The difference is quite clear. The boosted engine maintains a significant advantage in pressure throughout the power stroke, despite have no gain in peak pressure.

In reality, a boosted engine may be able to handle a small gain in peak as well, but the majority of the gain comes from average pressure.

140Airpower

Automotive

Komodo86, I assumed we were comparing turbocharged engines. With NA vs boosted, the BMEP of the boosted engine will definitely be higher, perhaps much higher while the peak pressure could be the same or even lower if the intake temperature is higher (the compressed charge autoignites at the about same temperature NA or boosted). The same or lower peak pressure would be from a reduced CR in the boosted engine.

Lou Scannon

Automotive

The other key thing to note in Komodo's diagram is the heat release for the turbocharged case is delayed relative to the normally aspirated case. Generally speaking, this would be due to a combination of reduced compression ratio and spark advance, compared with the NA engine.

The delayed heat release equates to lower indicated efficiency, all other things being equal. Of course, assuming the turbocharged engine is downsized accordance with its higher BMEP, there should be a relative increase in mechanical effiency, and significant reduction in engine mass, which should cascade onto lower vehicle mass, even with the same vehicle interior dimensions and load capacity.

Since we're only looking at one operating point, I can only speculate what the comparison of brake efficiency looks like over a realistic drive cycle, and what the actual fuel economy comparison would look like considering the difference in vehicle mass, not to mention the probable reduction in average pumping losses for the downsized engine.

Getting back to peak cylinder pressures; it seems that the cutting edge for commercial diesel engines these days is around 3000 psi. I think it's fair to assume we're talking about iron heads and steel piston crowns here. In the case of an Otto-cycle engine, neither of these are helpful for avoiding knock, compared to aluminum, but at least they can handle higher levels of mechanical & thermal stress; which might buy some knock margin on the mechanical side, assuming the rest of the vulnerable components (fire rings, bearings, rods, spark plugs, head gasket) are equally up to the task.

"Schiefgehen will, was schiefgehen kann" - das Murphygesetz

The delayed heat release equates to lower indicated efficiency, all other things being equal. Of course, assuming the turbocharged engine is downsized accordance with its higher BMEP, there should be a relative increase in mechanical effiency, and significant reduction in engine mass, which should cascade onto lower vehicle mass, even with the same vehicle interior dimensions and load capacity.

Since we're only looking at one operating point, I can only speculate what the comparison of brake efficiency looks like over a realistic drive cycle, and what the actual fuel economy comparison would look like considering the difference in vehicle mass, not to mention the probable reduction in average pumping losses for the downsized engine.

Getting back to peak cylinder pressures; it seems that the cutting edge for commercial diesel engines these days is around 3000 psi. I think it's fair to assume we're talking about iron heads and steel piston crowns here. In the case of an Otto-cycle engine, neither of these are helpful for avoiding knock, compared to aluminum, but at least they can handle higher levels of mechanical & thermal stress; which might buy some knock margin on the mechanical side, assuming the rest of the vulnerable components (fire rings, bearings, rods, spark plugs, head gasket) are equally up to the task.

"Schiefgehen will, was schiefgehen kann" - das Murphygesetz

I've now posted the model I used in the above post online as an interactive web app.

It's still a work in progress. I'd welcome any feedback!

It's still a work in progress. I'd welcome any feedback!

hemi said:I can only speculate what the comparison of brake efficiency looks like over a realistic drive cycle, and what the actual fuel economy comparison would look like considering the difference in vehicle mass, not to mention the probable reduction in average pumping losses for the downsized engine.

In my experiences, turbocharging small block Ford's in 3800 lbs cars, fuel economy usually increases from 22-26mpg N/A to 28-31 mpg under similar cruising conditions

GregLocock

Automotive

With no other changes? gosh that's amazing.

Cheers

Greg Locock

New here? Try reading these, they might help FAQ731-376

Cheers

Greg Locock

New here? Try reading these, they might help FAQ731-376

Lou Scannon

Automotive

Like Greg, I find that amazing also.

"Schiefgehen will, was schiefgehen kann" - das Murphygesetz

"Schiefgehen will, was schiefgehen kann" - das Murphygesetz

140Airpower

Automotive

Decipha, that result is counter to what I would expect from a turbo installation on a car. Aftermarket turbos are most often installed for performance and are usually not optimized for economy. Can you tell us details such as do you include a wastegate?

- Status

- Not open for further replies.

Similar threads

- Replies

- 22

- Views

- 3K

- Replies

- 16

- Views

- 1K

- Replies

- 4

- Views

- 2K

- Replies

- 1

- Views

- 513