Does anyone know of specific design criteria, technical notes, etc. for the design and placement of expansion joints used in slab-on-grades?

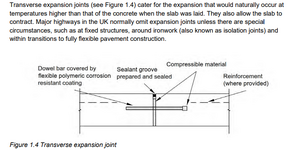

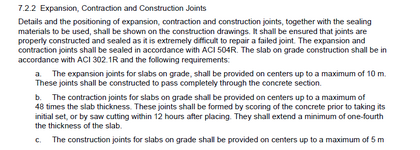

I'm NOT referring to contraction joints/control joints used to provide a pre-determined crack location. I'm referring to expansion of exterior slabs that experience thermal fluctuations.

I'm NOT referring to contraction joints/control joints used to provide a pre-determined crack location. I'm referring to expansion of exterior slabs that experience thermal fluctuations.