CNSZU

Mechanical

- Sep 2, 2005

- 318

Hi everyone,

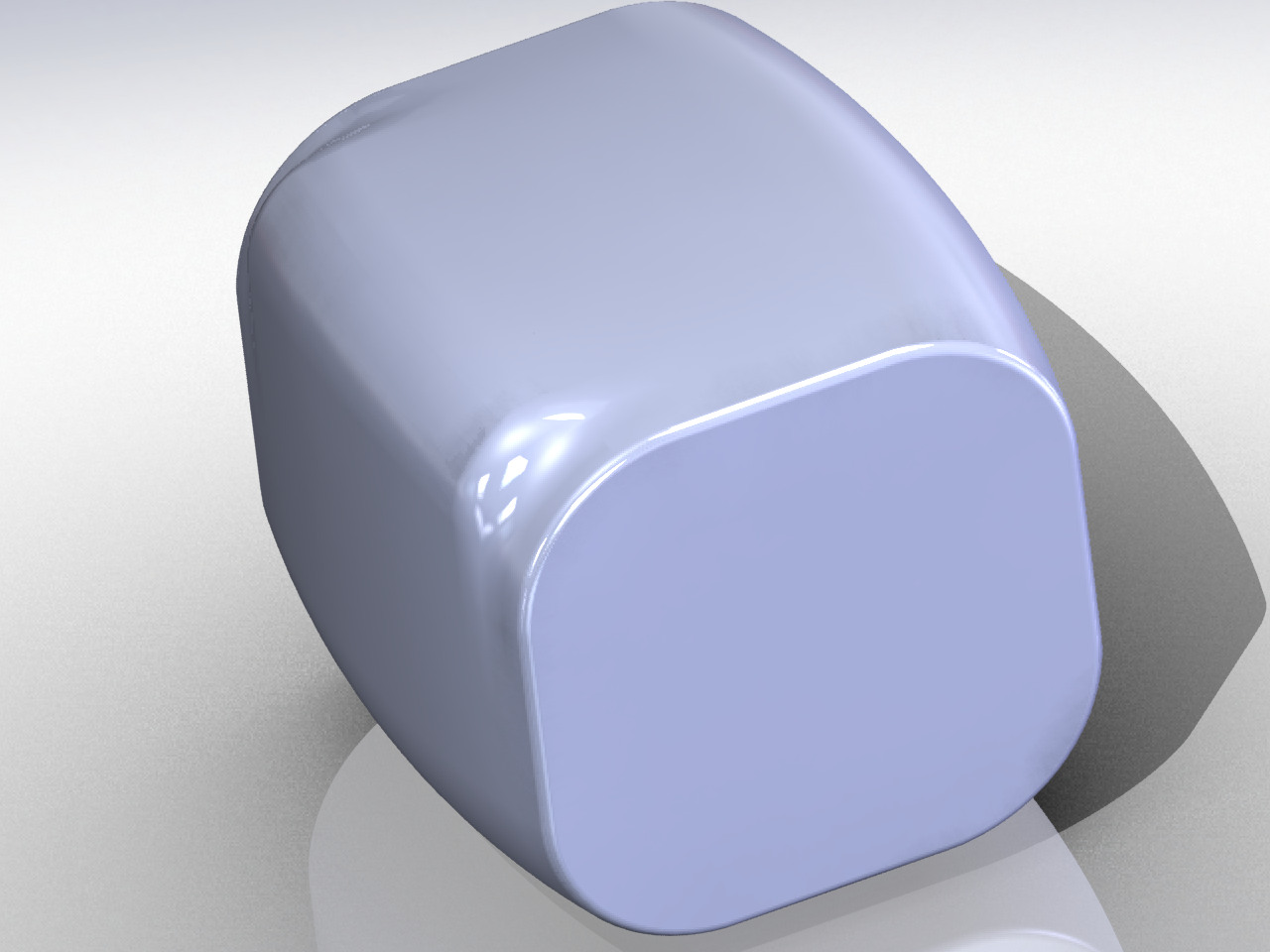

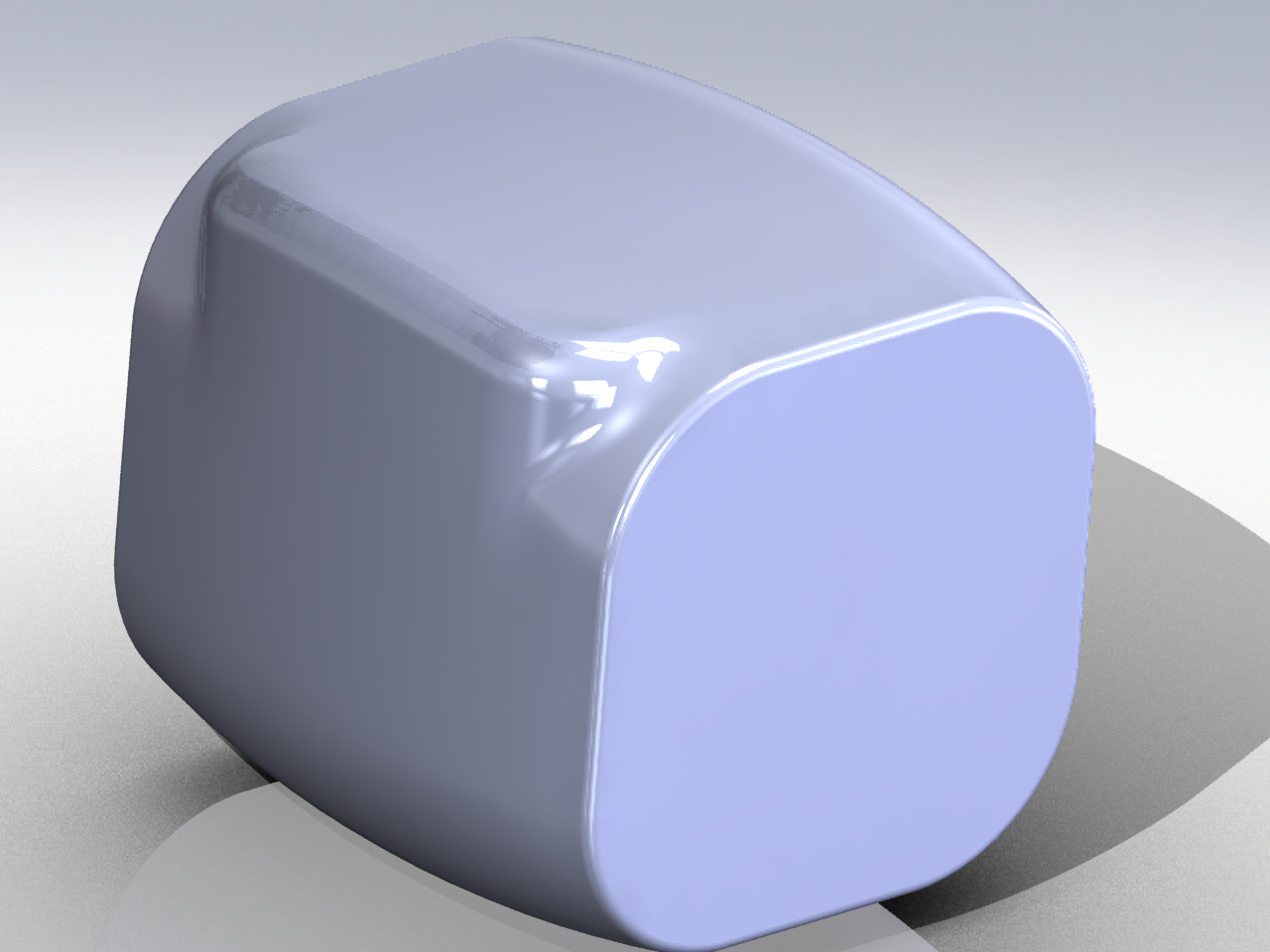

I finally managed to create this part more or less how I want it using surface techniques, because it's impossible building the exact same part with solids. Even then, the allowed range of fillet size is very limited, and will easily fail to create fillets. Why is this part so difficult? Is solidworks not suitable to create this kind of part? Should I use a surfacing tool, like Alias or Rhino instead?

I finally managed to create this part more or less how I want it using surface techniques, because it's impossible building the exact same part with solids. Even then, the allowed range of fillet size is very limited, and will easily fail to create fillets. Why is this part so difficult? Is solidworks not suitable to create this kind of part? Should I use a surfacing tool, like Alias or Rhino instead?