Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations cowski on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flowrate in a valve

- Thread starter Thuba

- Start date

- Status

- Not open for further replies.

LittleInch

Petroleum

Depends on your system design, but in general if you increase pressure drop across a valve then the flowrate will be lower than if the valve pressure drop as not there.

If though you have a PD pump this might not be the case.

Pressure drop and flow are linked, but each system is different to know what the impact will be.

If though you have a PD pump this might not be the case.

Pressure drop and flow are linked, but each system is different to know what the impact will be.

goutam_freelance

Mechanical

Yes! But PD pump discharge pressure may increase.f though you have a PD pump this might not be the case.

I don't know how advanced you are in engineering Fluids but here is the answer:

Say you have a long straight pipe between two water tanks. At the inlet side the water tank is has a liquid level of say 30 feet and at the outlet of the pipe the tank has a liquid level of 0 feet. Consider that the tank at inlet is constantly being fed with liquid so that it does not decrease or increase in level as liquid flows out of it.

In this case the pressure at the nozzle of the inlet tank or inlet of the pipe is 13 psig and at the pipe exit at the discharge tank is 0 psig. So there is a constant pressure at inlet and outlet of pipe so there is a constant differential pressure available to produce flow.

If there were no friction loss in the pipe then the all the pressure head 13 psig (30 feet) would be converted totally into kinetic energy V^2/2g. Where

V is velocity and g is an acceleration constant 32.2 ft/sec^2. Therefore V = SQRT (30*2*32.2) = 44 feet/sec. So if you have a pipe that is say 0.5 ft^2 in area the flow would be Q = V*A = 44*0.5 = 22 ft^3/sec.

Now account for friction loss in pipe and the addition of a check valve. At a given flowrate or velocity in the pipe there is a head loss across the pipe and check valve equal that is proportional to KV^2/2g. This reduces from the available head on the inlet of 30 feet liquid height. So as the velocity increases the head loss of the pipe friction and valve friction increases until a velocity is reached such that Velocity Head in pipe plus frictional losses = available differential head = 30 feet.

Differential Pressure = 30 feet = Kinetic Energy of Fluid + loss across piping + loss across check valve = V^2/2g + KV^2/2g (pipe) + KV^2/2g (valve)

So you can see that the more components you put into the line will reduce from the available 30 feet head available. If at a given flow/velocity the pipe loss is say 10 feet and the check valve loss is 5 feet for a total of 15 ft losses, then there is now only 15 feet available to go into the velocity/kinetic energy.

KE = V^2/2g = 15 feet or:

V= SQRT(15*2*32.2) = 31 feet/sec.

Now in the same pipe with 0.5 ft^2 area the flow will be Q = 31*0.5 = 15.5 Cu. ft. per second.

Therefore the friction loss in the pipe due to pipe friction and added check valve has reduced the maximum potential flow. Keep adding components in the piping and you will keep decreasing the flow relative to the maximum possible for a given available differential pressure.

Related to your question if a valve reduces flowrate? You must mean a block valve such as a gate or ball valve. The pressure drop across a fully open valve will reduce the flowrate as indicated above just due to the pressure drop across the valve body. In addition you can induce additional pressure drop across the valve by partially closing the valve. The more you close it the more pressure drop loss you create across the valve. The more pressure drop you create across the valve the less available for kinetic energy of the flow so the flow will be less and less as you close the valve more and more.

Say you have a long straight pipe between two water tanks. At the inlet side the water tank is has a liquid level of say 30 feet and at the outlet of the pipe the tank has a liquid level of 0 feet. Consider that the tank at inlet is constantly being fed with liquid so that it does not decrease or increase in level as liquid flows out of it.

In this case the pressure at the nozzle of the inlet tank or inlet of the pipe is 13 psig and at the pipe exit at the discharge tank is 0 psig. So there is a constant pressure at inlet and outlet of pipe so there is a constant differential pressure available to produce flow.

If there were no friction loss in the pipe then the all the pressure head 13 psig (30 feet) would be converted totally into kinetic energy V^2/2g. Where

V is velocity and g is an acceleration constant 32.2 ft/sec^2. Therefore V = SQRT (30*2*32.2) = 44 feet/sec. So if you have a pipe that is say 0.5 ft^2 in area the flow would be Q = V*A = 44*0.5 = 22 ft^3/sec.

Now account for friction loss in pipe and the addition of a check valve. At a given flowrate or velocity in the pipe there is a head loss across the pipe and check valve equal that is proportional to KV^2/2g. This reduces from the available head on the inlet of 30 feet liquid height. So as the velocity increases the head loss of the pipe friction and valve friction increases until a velocity is reached such that Velocity Head in pipe plus frictional losses = available differential head = 30 feet.

Differential Pressure = 30 feet = Kinetic Energy of Fluid + loss across piping + loss across check valve = V^2/2g + KV^2/2g (pipe) + KV^2/2g (valve)

So you can see that the more components you put into the line will reduce from the available 30 feet head available. If at a given flow/velocity the pipe loss is say 10 feet and the check valve loss is 5 feet for a total of 15 ft losses, then there is now only 15 feet available to go into the velocity/kinetic energy.

KE = V^2/2g = 15 feet or:

V= SQRT(15*2*32.2) = 31 feet/sec.

Now in the same pipe with 0.5 ft^2 area the flow will be Q = 31*0.5 = 15.5 Cu. ft. per second.

Therefore the friction loss in the pipe due to pipe friction and added check valve has reduced the maximum potential flow. Keep adding components in the piping and you will keep decreasing the flow relative to the maximum possible for a given available differential pressure.

Related to your question if a valve reduces flowrate? You must mean a block valve such as a gate or ball valve. The pressure drop across a fully open valve will reduce the flowrate as indicated above just due to the pressure drop across the valve body. In addition you can induce additional pressure drop across the valve by partially closing the valve. The more you close it the more pressure drop loss you create across the valve. The more pressure drop you create across the valve the less available for kinetic energy of the flow so the flow will be less and less as you close the valve more and more.

Last edited:

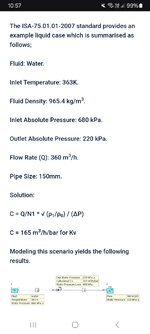

So the valve data sheet shows at a flowrate of 360 m^3/hr there is a pressure drop of 460 kPa across the valve. The equations at the bottom of the data sheet give the Cv flow coefficient of the valve which allows you to calculate the pressure drop across the valve for any flowrate. So if you want to design your system for a given flowrate say 360 m^3/hr shown, you will then have to deduct 460 kPa across the valve from the total available system differential pressure. It is not that the flowrate is not affected, but it is assumed a given flowrate and then the pressure drop across the valve is determined. However the flowrate that you assume (design the system for) can only be obtained if the sum of all pressure drops across all piping components (including the 460 kPa loss across the valve) equals your available differential pressure. After you subtract all the losses for valves and other piping components at a given flowrate, the sum of pressure piping pressure drops must be equal to the actual available differential pressure to get the assumed flowrate. The valve data sheet below just gives you the pressure drop across one piping component at a given flowrate. You must add this one pressure drop to all pressure drops in the piping system to get the total pressure drop.

If the flowrate you chose/design for gets you a lower pressure drop in all the piping components then the actual flowrate will be higher until the sum of pressure drops across piping components equals the available differential pressure, if you really want to maintain a flow with a lower pressure drop then available then you would install a manual valve, control valve, or restriction orifice to artificially induce more pressure loss to get the exact flow you need. If the flowrate you chose gets a higher sum of pressure drops across components then the actual flowrate will be lower than what your assumption was. If you really need higher flowrate then you will need to upsize your pipe to reduce the pressure loss. This is how you determine the flowrate in a pipe for a given set of components and pressure drop - sum of pressure drops equals available differential pressure is where the flowrate will be in equilibrium.

If the flowrate you chose/design for gets you a lower pressure drop in all the piping components then the actual flowrate will be higher until the sum of pressure drops across piping components equals the available differential pressure, if you really want to maintain a flow with a lower pressure drop then available then you would install a manual valve, control valve, or restriction orifice to artificially induce more pressure loss to get the exact flow you need. If the flowrate you chose gets a higher sum of pressure drops across components then the actual flowrate will be lower than what your assumption was. If you really need higher flowrate then you will need to upsize your pipe to reduce the pressure loss. This is how you determine the flowrate in a pipe for a given set of components and pressure drop - sum of pressure drops equals available differential pressure is where the flowrate will be in equilibrium.

- Status

- Not open for further replies.

Similar threads

- Replies

- 36

- Views

- 16K

- Replies

- 0

- Views

- 8K