medeek

Structural

- Mar 16, 2013

- 1,104

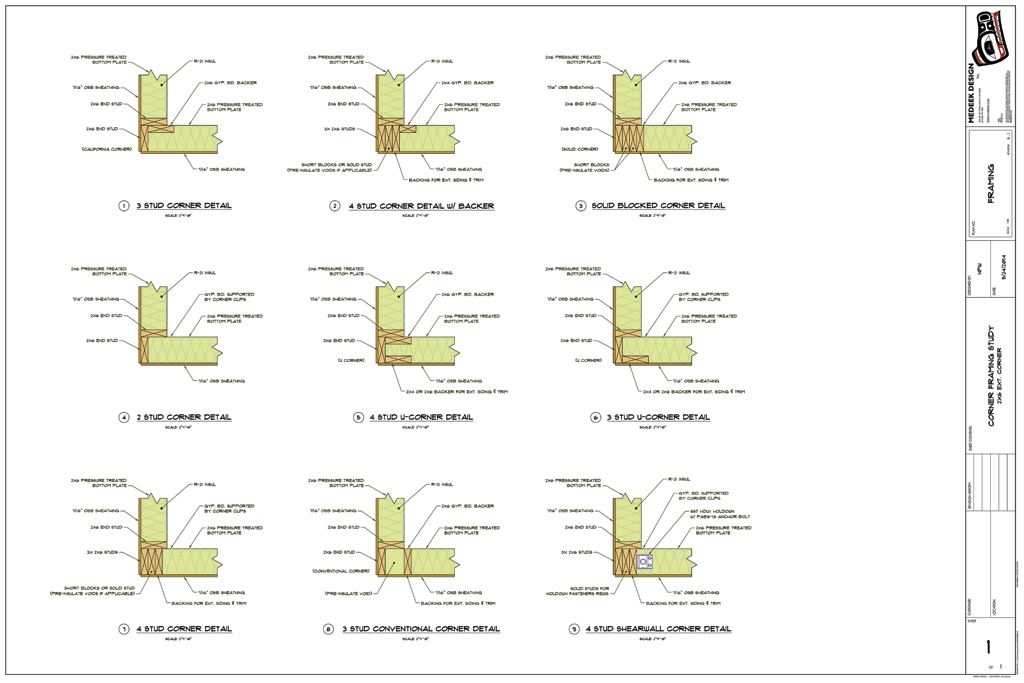

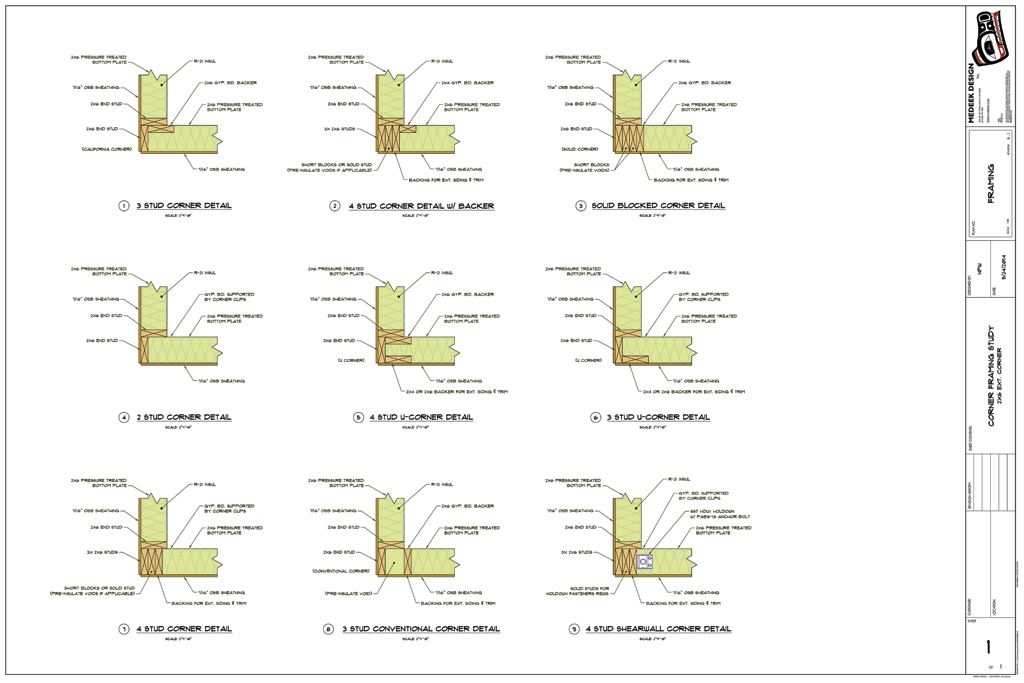

I've been struggling with the best way to frame ext. corners on 2x6 walls so I looked through a number of my framing texts and online and put together a small matrix with a number of methods.

A high resolution PDF file is here:

I do a lot of designs with hardiplank siding so good backing for the trim and siding is important to me. Up until now I've been specifying Detail 2 a lot, but now I'm looking at Detail 5 and it seems to offer the same advantages and more. Any thoughts?

A high resolution PDF file is here:

I do a lot of designs with hardiplank siding so good backing for the trim and siding is important to me. Up until now I've been specifying Detail 2 a lot, but now I'm looking at Detail 5 and it seems to offer the same advantages and more. Any thoughts?

![[idea] [idea] [idea]](/data/assets/smilies/idea.gif)

![[r2d2] [r2d2] [r2d2]](/data/assets/smilies/r2d2.gif)