tmgczb

Structural

- May 12, 2021

- 174

As the title, if friction between backfilling soil in tank ring wall and soil base is considered in resisting sliding, how to determine the friction coefficient?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Please specify.Use the worst case friction angle.

This is not self-anchored tank. There are anchor bolts.My points for the sliding design of AST with ring wall found.

- Shear Strength of Soil τf = c + σ Tan ø

- ASCE 7 suggests for sliding resistance , the friction coefficient at base of footing would be 0.67 Tan ø . This resistance would be multiplied with Resistance factor, φ= 0.85 per Table 12.13-1 of the Standard. ( This is for strength design )

- API 650 relevant clauses ;

5.11.4 Sliding Friction

Unless otherwise required, tanks that may be subject to sliding due to wind shall use a maximum allowable sliding

friction of 0.40 multiplied by the force against the tank bottom.

E.7.6 Sliding Resistance

The transfer of the total lateral shear force between the tank and the subgrade shall be considered.

For self-anchored flat-bottom steel tanks, the overall horizontal seismic shear force shall be resisted by friction

between the tank bottom and the foundation or subgrade. Self-anchored storage tanks shall be proportioned such

that the calculated seismic base shear, V, does not exceed Vs:

The friction coefficient, , shall not exceed 0.4. Lower values of the friction coefficient should be used if the interface

of the bottom to supporting foundation does not justify the friction value above (e.g., leak detection membrane

beneath the bottom with a lower friction factor, smooth bottoms, etc.).

If this is for AST found. design , i will suggest you to limit the friction coefficient, fmax= 0.4.

And the anchor bolts have to account for the thermal expansion of the ring plate. So the holes have be larger and the connection of the bolt some where above the ring base plate. If the bolts have to resist uplift, we usually will add in a small P-delta moment/S to the tension force of Pt/A.This is not self-anchored tank. There are anchor bolts.

Sliding resistance will be practically the same . The mechanically-anchored tanks which are normally equipped with traditional anchor bolts and chairs at least 450 mm high are not prevented from sliding laterally at least 25 mm .This is not self-anchored tank. There are anchor bolts.

Sliding resistance will be practically the same . The mechanically-anchored tanks which are normally equipped with traditional anchor bolts and chairs at least 450 mm high are not prevented from sliding laterally at least 25 mm .

The relevant clause ;

E.7.6 Sliding Resistance

...No additional lateral anchorage is required for mechanically-anchored steel tanks designed in accordance with this

Annex even though small movements of approximately 25 mm (1 in.) are possible.

- I will suggest you , next time prefer to post at Storage Tank forum. You probably may get more better responds.

I will read.Tipping over is fall or turn over of the tank.

Earthquake causes movement of objects supported on the ground and lateral forces on tank cause the tank contents to slosh which creates an overturning

moment at the base of the tank. OT may lead to uplift of one side if the tank is not anchored. If the uplift is small, some portion of the liquid resists to overturning together with the shell. If the seismic force large enough and the tank is not anchored, the tank may overturn / tip over.

I will suggest you to look the following paper then ask if the subject still not clear.

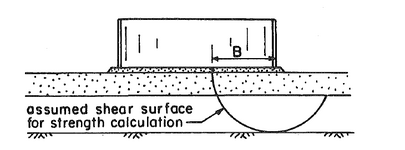

Your guess is not correct. These are the soil failure types which shall be checked for design of storage tank foundation.It says that punching shear, edge shear and base shear need to be verified.

I consider edge shear is what we call one-way shear.

In this way punching shear here is not what we check for depth of footing.Your guess is not correct. These are the soil failure types which shall be checked for design of storage tank foundation.

Short answer;

- Base shear failure : total shear failure of the entire tank foundation soil . Just look any foundation design book and allowable stress for spread footings,

- Edge shear failure : Local failure of a part of the tank perimeter together with some portion of the base. ( The following picture ).

View attachment 5279

- punching shear failure : failure of the supporting soil under the footing . Failure type C at the following figure.

View attachment 5278

Each failure type should be assesed by an experienced geotech eng.

These are basic knowledge and you could reach even just by searching the web.

Next time we are waiting more serious questions.