By 'GA' I assume you mean 'General Arrangement' drawings, eh?

When I was still working in the 'real world', back in Michigan, the company I worked for had to create what we called 'Connection Drawings' which I assume is similar to what you're talking about. Now we built capital machinery for the baking industry and the first 'drawing' delivered to a customer was the 'Connection Drawing' for the oven since that was generally the longest lead time and the one which potentially required the most effort by the customer and his building contractor. This included not only the location and specifications for the various 'connections' to the electrical service, gas service, steam (based on the product that would be baked and the options on the oven), exhaust stacks, as well as foundations, drains, clearances needed for access by maintenance personnel, and even recommendations about the special considerations needed for fire suppression, sprinkler systems and heat & smoke detectors.

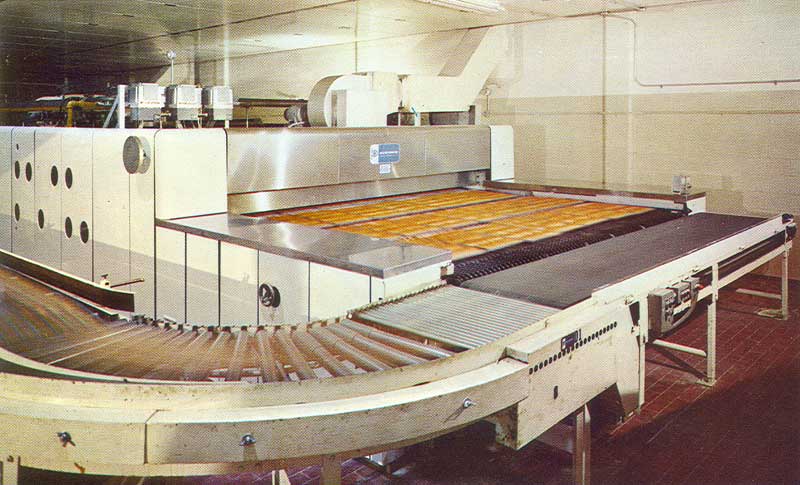

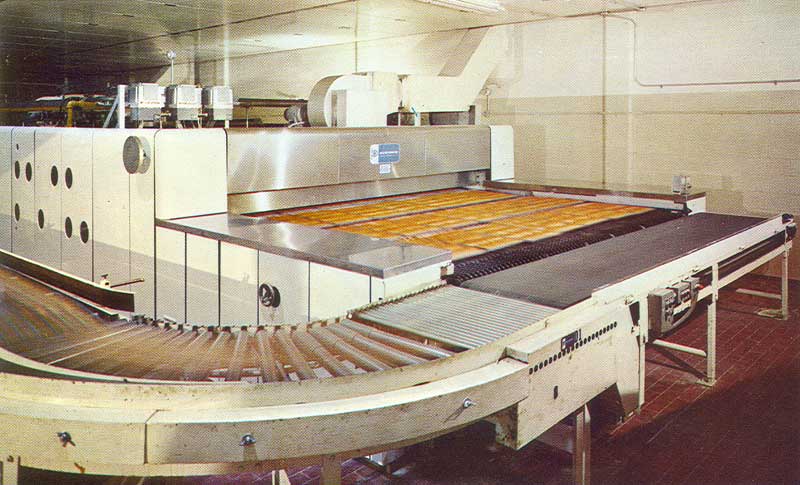

Those last items I can attest to personally as to what can happen if you have a customer who ignores the 'fine print'. I was assigned to help with a start-up of a couple of production lines out in East Hartford (Connecticut) one year (it was winter time, the relevance of which will be obvious in a moment). A large grocery chain had converted a warehouse to house their new bakery and we had just started up the first of 3 lines, complete with proofer, oven, cooler, etc. (these were highly automated with conveyors transfering bread/roll pans from one automated machine to the next, typical examples of which are shown here)...

Anyway, we had been running at full temperature (approx 450°F) for about 4 or 5 hours and the first test bake was just coming out of the oven when the overhead sprinker system let loose. Unless you've actually witnessed one personally, you have NO IDEA how much water can come from just one of those industrial-sized sprinker heads. It's amazing, and remember, I said this was in the winterso , IT WAS COLD! And when that water hit the hot oven it was immediately converted to steam which not only prevented you from seeing anything, it was also dangerous as you could get severly scalded. And then you had the problem of a very hot and large moving machine being dumped-on with water at around 35°-40° which can cause steel to warp and drive systems to jam. Needless to say, it was a mess, in so many ways ;-)

Well, it turns out that that no one had thought to check-out and replacing the low-temp warehouse sprinker heads with high-temp heads more suitable for a bakery or factory type environment. It was a lesson learned the hard way as to not assume that your customer had actually read and performed those tasks which were part of his responsibility to complete.

John R. Baker, P.E.

Product 'Evangelist'

Product Engineering Software

Siemens PLM Software Inc.

Industry Sector

Cypress, CA

UG/NX Museum:

To an Engineer, the glass is twice as big as it needs to be.