Hello, this question is related to my other post regarding idler gear mounting.

Design Background:

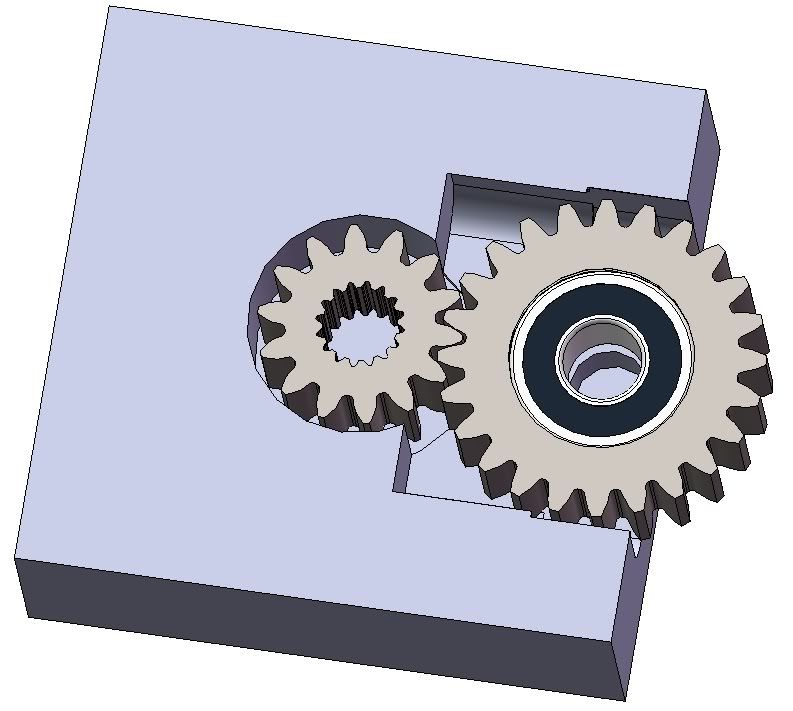

I have designed a pinion-idler train housing that mounts to a customer-supplied driven gear housing. My idler gear sticks part way out of my housing in order to accomplish this. All the gears in the gear train (pinion, idler, driven) are in a "row" so to speak (centers of rotation line along a line).

I had assumed that the customer would address the grease requirement of the gears when mating the two housings. However, they have requested that my pinion-idler housing include provisions for the addition of grease (I'm assuming the customer will add grease as needed as part of regular maintenance schedule). SO, I added a "Zerk" type fitting to my pinion-idler housing.

________________________________

Question:

This is where I have some questions regarding the lubrication requirement of gears.

Are there general guidelines or requirements for radial clearance over the tooth of the gears (max or min) to allow for the distribution and movement of grease within the housing???

Will any movement of the grease occur?

I currently have the Zerk fitting feeding into the pinion pocket pointing towards the idler pocket. My reasoning being that as grease is pumped into the pinion pocket, it will fill and extrude into the idler pocket etc.

Any comments or suggestions are appreciated.

Thanks.

Beat to fit, paint to match.

Design Background:

I have designed a pinion-idler train housing that mounts to a customer-supplied driven gear housing. My idler gear sticks part way out of my housing in order to accomplish this. All the gears in the gear train (pinion, idler, driven) are in a "row" so to speak (centers of rotation line along a line).

I had assumed that the customer would address the grease requirement of the gears when mating the two housings. However, they have requested that my pinion-idler housing include provisions for the addition of grease (I'm assuming the customer will add grease as needed as part of regular maintenance schedule). SO, I added a "Zerk" type fitting to my pinion-idler housing.

________________________________

Question:

This is where I have some questions regarding the lubrication requirement of gears.

Are there general guidelines or requirements for radial clearance over the tooth of the gears (max or min) to allow for the distribution and movement of grease within the housing???

Will any movement of the grease occur?

I currently have the Zerk fitting feeding into the pinion pocket pointing towards the idler pocket. My reasoning being that as grease is pumped into the pinion pocket, it will fill and extrude into the idler pocket etc.

Any comments or suggestions are appreciated.

Thanks.

Beat to fit, paint to match.