XR250

Structural

- Jan 30, 2013

- 5,274

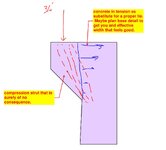

We thought the wall was solid the entire way to the footing. Turns out there is a haunch. My demand is 3.8k service. The EOR wants us to cut thru the haunch and bolt the column to the concrete wall below using a plate. I don't do much R/C design but my gut says this should be able to handle 3.8k. What are y'all's thoughts?