[Cross-posted in the PLC forum. Mods, please merge these or close one if cross-posting is not allowed.]

Hi all. Please be gentle, I’m an ME and I know very little about PLCs / Process control. I think I have a bit of an unusual application here.

We have a VERY expensive (as in, in the same ballpark as the price of a nice house) avionics computer in a ground based simulator that we cool with ambient air supplied by a small fan (originally a residential furnace draft inducer fan).

We currently use a basic, fixed setpoint pressure switch on the outlet of the fan to monitor the fan pressure. If the fan fails and is no longer supplying 1”W.C. of pressure, the pressure switch opens, which tells our system to shut off power to the computer.

But unfortunately we recently discovered a failure mode that this system did not catch, where our fan failed partially. It was still spinning and delivering enough pressure to keep the pressure switch closed, but not enough to adequately cool the computer. The computer overheated and failed.

The first thought then was that we need our pressure switch set to a higher setpoint. We’ve spoken with the people who involved with the design and everyday test and application of these computers, and still are not able to figure exactly what pressure we'd want to set our switch to (or flow rate if we were to use a flow switch instead of a pressure switch).

But if we take a step back, the parameter we’re really concerned with is the temperature of the computer itself.

So we’re wanting to find a solution that allows us to monitor both the temperature of the computer (with a surface mount thermocouple or possibly an IR pyrometer) and the fan status (likely with a pressure transducer/switch) and control based on those 2 inputs.

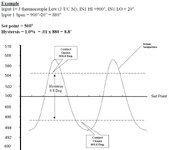

We’d like to program it such that if the fan fails to produce a given pressure, or the computer gets too hot, a relay opens which will tell our PDU to shut off power to the computer. We’d also like to have an intermediate alarm (relay?) output, that will notify us if the computer is getting a little warm, so that we have some advanced warning that it’s getting a little hotter than we prefer before it gets to the critical temperature that will require us to shut it down. At the same time, we'd like to still monitor pressure downstream of our cooling fan, and ideally be able to trigger an alarm signal and power off the computer if the fan pressure drops below a certain setpoint.

Some type of serial communication interface (or maybe Ethernet? Not sure if our system would interface with that as easily as a serial protocol) would be great as well, so that we could view our computer’s temperature and fan pressure from our remote operator station.

To be clear, our cooling fan is a single speed fan, so we’re not trying to modulate or change fan speed for now, just to turn off the computer if it gets too hot (although it would be nice to get a controller that has the capability to modulate fan speed, as I would like to switch to more modern/reliable fans in the future that are speed controllable. BUT that will take some time for me to convince the “powers that be” to spend the money on that, if we can get the money to do it at all.)

I have a little bit of background in industrial/"heavy" commercial HVAC equipment, but as an ME, I don’t know as much about controls & programming as I wish I did.

Although I definitely wouldn’t mind learning the skill, I (and my manager) would prefer I not to have to have to spend the time to learn to program a PLC (or HVAC controller) if possible. If there’s no getting around that, what cheap, reliable options are out there that are relatively easy to learn? (I’m no Computer Science/software guy, but I do know my way around a computer enough to be pretty confident in Solidworks, NX (FKA UniGraphics), and Excel).

I'm thinking an industrial automation controller would be the cheaper & easier way (vs HVAC controls) to do what I’m wanting to do. Something a step down from a PLC in cost & complexity. Maybe one of these? https://www.automationdirect.com/ad...cess_controllers/advanced_process_controllers along with a thermocouple and one of these pressure transducers https://www.automationdirect.com/ad...ensors/pressure_transmitters/ptd25-10-0100wch

Or would it be best to keep the temperature and pressure monitoring separate in 2 devices, and use one of these for pressure https://www.automationdirect.com/ad...re_switches_-z-_transmitters/eps25-100wc-1001

And one of these for temperature https://www.automationdirect.com/ad...controllers/standard_temperature_controllers# ?

Or is there some small low cost but reliable HVAC controller out there that could do what I’m wanting to do without too much of a learning curve and/or time investment?

Or another simpler way that I'm overlooking?

Hi all. Please be gentle, I’m an ME and I know very little about PLCs / Process control. I think I have a bit of an unusual application here.

We have a VERY expensive (as in, in the same ballpark as the price of a nice house) avionics computer in a ground based simulator that we cool with ambient air supplied by a small fan (originally a residential furnace draft inducer fan).

We currently use a basic, fixed setpoint pressure switch on the outlet of the fan to monitor the fan pressure. If the fan fails and is no longer supplying 1”W.C. of pressure, the pressure switch opens, which tells our system to shut off power to the computer.

But unfortunately we recently discovered a failure mode that this system did not catch, where our fan failed partially. It was still spinning and delivering enough pressure to keep the pressure switch closed, but not enough to adequately cool the computer. The computer overheated and failed.

The first thought then was that we need our pressure switch set to a higher setpoint. We’ve spoken with the people who involved with the design and everyday test and application of these computers, and still are not able to figure exactly what pressure we'd want to set our switch to (or flow rate if we were to use a flow switch instead of a pressure switch).

But if we take a step back, the parameter we’re really concerned with is the temperature of the computer itself.

So we’re wanting to find a solution that allows us to monitor both the temperature of the computer (with a surface mount thermocouple or possibly an IR pyrometer) and the fan status (likely with a pressure transducer/switch) and control based on those 2 inputs.

We’d like to program it such that if the fan fails to produce a given pressure, or the computer gets too hot, a relay opens which will tell our PDU to shut off power to the computer. We’d also like to have an intermediate alarm (relay?) output, that will notify us if the computer is getting a little warm, so that we have some advanced warning that it’s getting a little hotter than we prefer before it gets to the critical temperature that will require us to shut it down. At the same time, we'd like to still monitor pressure downstream of our cooling fan, and ideally be able to trigger an alarm signal and power off the computer if the fan pressure drops below a certain setpoint.

Some type of serial communication interface (or maybe Ethernet? Not sure if our system would interface with that as easily as a serial protocol) would be great as well, so that we could view our computer’s temperature and fan pressure from our remote operator station.

To be clear, our cooling fan is a single speed fan, so we’re not trying to modulate or change fan speed for now, just to turn off the computer if it gets too hot (although it would be nice to get a controller that has the capability to modulate fan speed, as I would like to switch to more modern/reliable fans in the future that are speed controllable. BUT that will take some time for me to convince the “powers that be” to spend the money on that, if we can get the money to do it at all.)

I have a little bit of background in industrial/"heavy" commercial HVAC equipment, but as an ME, I don’t know as much about controls & programming as I wish I did.

Although I definitely wouldn’t mind learning the skill, I (and my manager) would prefer I not to have to have to spend the time to learn to program a PLC (or HVAC controller) if possible. If there’s no getting around that, what cheap, reliable options are out there that are relatively easy to learn? (I’m no Computer Science/software guy, but I do know my way around a computer enough to be pretty confident in Solidworks, NX (FKA UniGraphics), and Excel).

I'm thinking an industrial automation controller would be the cheaper & easier way (vs HVAC controls) to do what I’m wanting to do. Something a step down from a PLC in cost & complexity. Maybe one of these? https://www.automationdirect.com/ad...cess_controllers/advanced_process_controllers along with a thermocouple and one of these pressure transducers https://www.automationdirect.com/ad...ensors/pressure_transmitters/ptd25-10-0100wch

Or would it be best to keep the temperature and pressure monitoring separate in 2 devices, and use one of these for pressure https://www.automationdirect.com/ad...re_switches_-z-_transmitters/eps25-100wc-1001

And one of these for temperature https://www.automationdirect.com/ad...controllers/standard_temperature_controllers# ?

Or is there some small low cost but reliable HVAC controller out there that could do what I’m wanting to do without too much of a learning curve and/or time investment?

Or another simpler way that I'm overlooking?

Last edited: