stormloader

Aerospace

- Oct 16, 2014

- 15

Hello everyone,

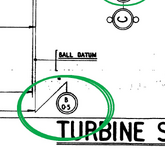

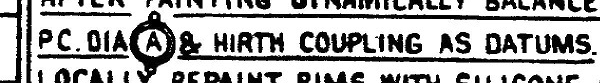

I have this old shaft drawing and I’ve circled several callouts in green. I guess they are geometrical tolerances, but I’m not exactly sure how to interpret them. I also don’t understand the numerical values inside their bubbles—what do they mean, and how should they be read?

Any insight into this would be greatly appreciated!

Thanks in advance.

I have this old shaft drawing and I’ve circled several callouts in green. I guess they are geometrical tolerances, but I’m not exactly sure how to interpret them. I also don’t understand the numerical values inside their bubbles—what do they mean, and how should they be read?

Any insight into this would be greatly appreciated!

Thanks in advance.