Hi All,

I'm hoping someone might be able to give me some advice on a shed project.

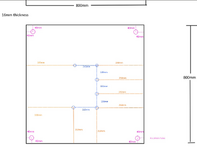

I have a 9m x 6m shed with a 32MPA concrete slab that is 100mm deep.

I had pierings of 400x 400x400mm for each column of the shed, as well as 2 additional pierings for a future installation of a car hoist.

Unfortunately the height of the hoist doesn't allow me to put it in those poisitions so I am no wleft with 2 options. The first is to cut out the concrete and dig the whole area out (4mx2m has been recommended) and then fill with new concrete, all of whch seems like a big job.

The other option is to use base extension plates to distribute the load across a larger surface area. There were some options available but they looked like they weren't quite up to the job, and none of the car hoist companies would give me anything in writing to say this would suffice.

I've asked a metal fabrication shop to make me some 800mm x 800mm x 16mm thick steel plates drilled to the current hoist column bolt pattern which I'm hoping will make up for the lack of concrete depth which is recommended at 150mm.

The hoist is a 4 tonne 2 post car hoist (Model TPB140) but I'll be using it for cars no heavier than 1.8tonne. Do you think these plates will distribute the weight enough to compensate?

I'm hoping someone might be able to give me some advice on a shed project.

I have a 9m x 6m shed with a 32MPA concrete slab that is 100mm deep.

I had pierings of 400x 400x400mm for each column of the shed, as well as 2 additional pierings for a future installation of a car hoist.

Unfortunately the height of the hoist doesn't allow me to put it in those poisitions so I am no wleft with 2 options. The first is to cut out the concrete and dig the whole area out (4mx2m has been recommended) and then fill with new concrete, all of whch seems like a big job.

The other option is to use base extension plates to distribute the load across a larger surface area. There were some options available but they looked like they weren't quite up to the job, and none of the car hoist companies would give me anything in writing to say this would suffice.

I've asked a metal fabrication shop to make me some 800mm x 800mm x 16mm thick steel plates drilled to the current hoist column bolt pattern which I'm hoping will make up for the lack of concrete depth which is recommended at 150mm.

The hoist is a 4 tonne 2 post car hoist (Model TPB140) but I'll be using it for cars no heavier than 1.8tonne. Do you think these plates will distribute the weight enough to compensate?