I'll do my best to answer these questions. I was hoping someone with experience in this field could tell me 10' piles seem reasonable or they are too short given your application. I'm on a condo board with non-technical members who tend to believe the contractor. My gut feeling with what I've read is that 10' is to short and would tend to push out at the bottom, but I'm no expert. The technical design documents referenced are quite intimidating someone not well versed on the subject matter.

Here is what the contractor quoted that they would do:

Mobilization of equipment & materials

Excavate behind existing timber deck to tie-back grade

Drive new SKL 12 x .217 thk x 10’ long sheets

Cut through tie-back rods to drive sheeting and re-weld rods back together

Weld a new C6 x 10.5# cap atop the sheeting

Backfill with existing excavated material

Given that I will try to answer the questions you posted and hopefully someone can give me more thoughts.

Is the sheet piling to be cantilevered or tied back? Cantilevered.

If tied back, where will the wale be located? None, just a C6 x 10.5# cap

Will it be in front of or behind the sheet piling? N/A

Is there room for the wale in front of the sheet piling? N/A

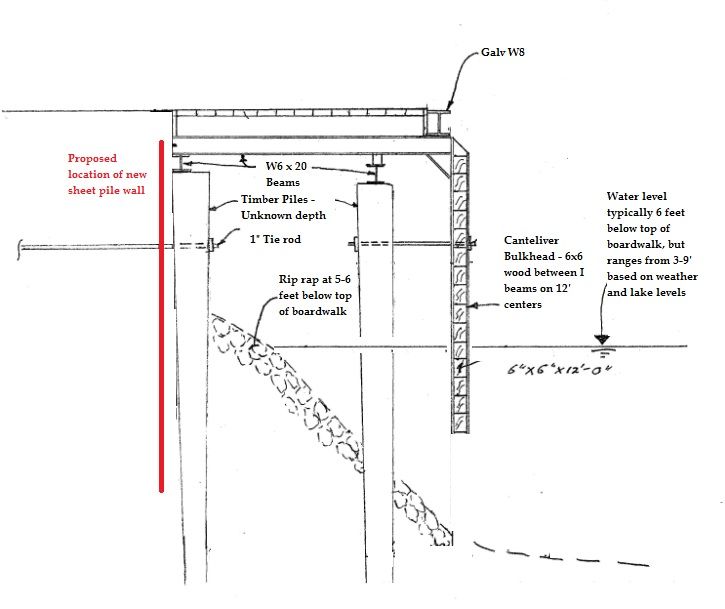

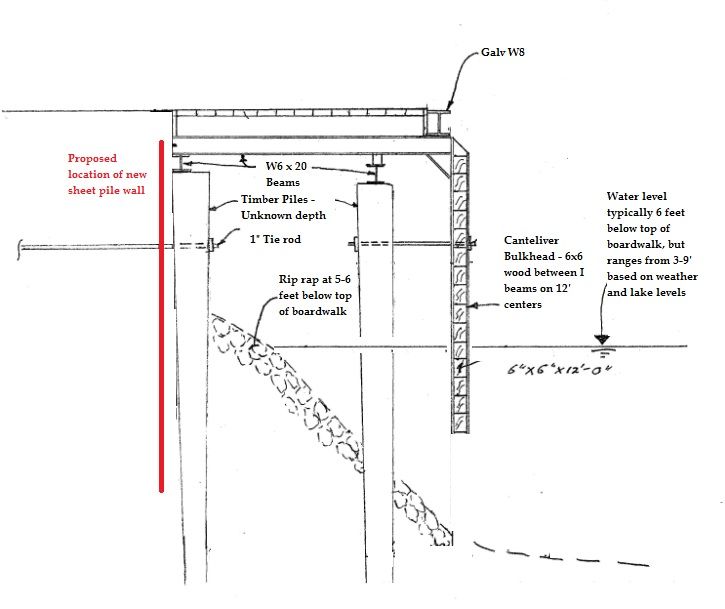

What and where is the existing tie rod and deadman system? There a are two wooden piles driven every 6' under the existing boardwalk to support it. Do not know how deep they are driven. Each wooden pile on the shore side has a tie back through it about 3-4' down that runs to a deadman about 15-20' back in the ground.

Is the existing tie rod and deadman system sufficient for the new structure? No idea, but it is 20 years

What is currently retaining the soil between the tiedback timber piles? The current retaining system is prone to failures hence we are looking to upgrade it. You'll find the current design interesting. A 7' chain link is strapped to the horizontal boardwalk beam closest the shore. It extends down about 4' and then tucks under the soil. Landscaping fabric is on the inside of the fencing. The fencing herniates and tears off the beam creating sink holes. This design is interesting in that it tends to pull down on the boardwalk rather than press against it. It also allows water to pass through so you build up very less hydraulic pressure and if pressures get too great it ruptures rather than damage the boardwalk. I'd hate to upgrade to a system that pushes the boardwalk over when it fails.