Hey all,

I only recently learned that the synchronous condensers I operated at one site some 40-ish years ago were previously 25 Hz/60 Hz frequency changers, and that when Ontario's frequency conversion program to 60 Hz was completed, the 25 Hz end machines were rebuilt to 60 Hz synchronous condensers.

I cannot find any records of how this would have been done, and it never occurred to me to look it up at the time, mostly because I just accepted their presence at face value and never inquired at the time as to why they were there . . . and it now surprises me that nobody said anything about this to this lowly trainee at the time.

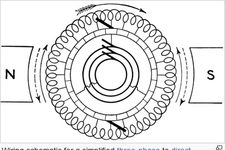

My speculative WAG is that the rotor could have been either replaced or the extant one rebuilt to operate satisfactorily at 720 rpm instead of 300 rpm, and that the windings would probably have been reconfigured form series to parallel operation in some fashion so as to address the cumulative voltage rise issue.

What I'm wondering about, though, is whether the stator lamination thicknesses would have worked in this new configuration, if there would have been eddy current and other loss issues that this would have caused, etc., etc.

Thoughts?

I only recently learned that the synchronous condensers I operated at one site some 40-ish years ago were previously 25 Hz/60 Hz frequency changers, and that when Ontario's frequency conversion program to 60 Hz was completed, the 25 Hz end machines were rebuilt to 60 Hz synchronous condensers.

I cannot find any records of how this would have been done, and it never occurred to me to look it up at the time, mostly because I just accepted their presence at face value and never inquired at the time as to why they were there . . . and it now surprises me that nobody said anything about this to this lowly trainee at the time.

My speculative WAG is that the rotor could have been either replaced or the extant one rebuilt to operate satisfactorily at 720 rpm instead of 300 rpm, and that the windings would probably have been reconfigured form series to parallel operation in some fashion so as to address the cumulative voltage rise issue.

What I'm wondering about, though, is whether the stator lamination thicknesses would have worked in this new configuration, if there would have been eddy current and other loss issues that this would have caused, etc., etc.

Thoughts?