I have a quick question about threads. I am trying to design a part with a threaded connection and it needs to be able to handle up to 1800 ft*lbf of torque. After doing this, I am only getting around 1200 ft*lbf. Would increasing my thread length help me reach the 1800 ft*lbf that I am trying to design for. I cannot change the size of the threads.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations cowski on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Increasing thread length

- Thread starter jhmche

- Start date

- Status

- Not open for further replies.

Thread length, probably not. More thread engagement, maybe. I don't know your design.

Chris, CSWA

SolidWorks '15

SolidWorks Legion

Chris, CSWA

SolidWorks '15

SolidWorks Legion

Within limits what you are proposing can work, a quick bit of Googling may give you some idea of what these limits are, with a quick search I found:

(Or if you don't like PDF

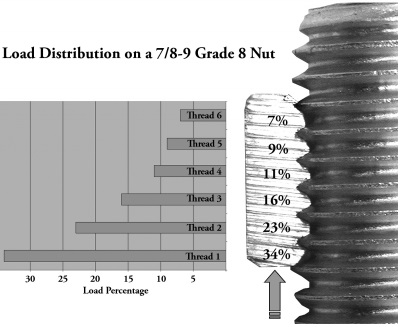

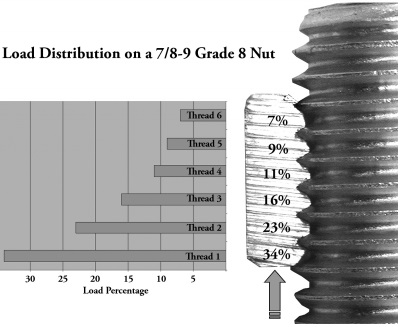

[URL unfurl="true" said:https://www.fastenal.com/content/feds/pdf/Article%20-%20Screw%20Threads%20Design.pdf[/URL]]Caution: It appears that one could theoretically increase the thread strength by increasing the length of engagement. However, as illustrated in the Load Distribution chart above, the first thread will be taking the majority of the applied load. For carbon steel fasteners (including tapped holes) the length of engagement would be limited to approximately one nominal diameter (approximately 1-1/2 times the diameter for aluminum). After that, there is no appreciable increase in strength. Once the applied load has exceeded the first thread’s capacity, it will fail and subsequently cause the remaining threads to fail in succession.

(Or if you don't like PDF

Posting guidelines faq731-376 (probably not aimed specifically at you)

What is Engineering anyway: faq1088-1484

What is Engineering anyway: faq1088-1484

By the way, if you need higher strength threaded connection there are other variables to play with other than nominal diameter and thread engagement & at least one other mentioned in the link I gave you.

Consider thread form for instance, I suggest you research terms such as "buttress thread"; "square thread" and "trapezoidal thread".

Consider thread form for instance, I suggest you research terms such as "buttress thread"; "square thread" and "trapezoidal thread".

Posting guidelines faq731-376 (probably not aimed specifically at you)

What is Engineering anyway: faq1088-1484

What is Engineering anyway: faq1088-1484

The requirements in the OP were a bit vague. What is the relationship between applied torque and capacity of the threaded connection? The most obvious solution to increasing the wrenching torque capacity of your threaded connection without changing any of the thread dimensions would be to increase the static friction value used in your calculations. All it would need to increase the wrenching torque from 1200 ft-lb to 1800 ft-lb for a given axial preload is to increase the friction value used in the analysis by 50%.

Hi jhardy47

We need a lot more information like the size/grade of fastener and the materials clamped in the joint that are being used,a bit more information about the application.

Also what is happening to the joint at at 1200lbsft? Are the threads failing?

If the joint is failing then you would be better off changing the materials either the fastener or the materials within the joint,depending on which as failed.

In theory increasing the thread engagement would increase the torque that the joint could withstand however that's only true if you assume that each thread takes an equal share of the load, in practice once the thread engagement as reached about 1.5 to 2 times the bolt diameter there is little to be gained after that.

Another way to increase the joint strength might be to fit a helicoil insert but this would only work if it's the female thread that's failing.

“Do not worry about your problems with mathematics, I assure you mine are far greater.” Albert Einstein

We need a lot more information like the size/grade of fastener and the materials clamped in the joint that are being used,a bit more information about the application.

Also what is happening to the joint at at 1200lbsft? Are the threads failing?

If the joint is failing then you would be better off changing the materials either the fastener or the materials within the joint,depending on which as failed.

In theory increasing the thread engagement would increase the torque that the joint could withstand however that's only true if you assume that each thread takes an equal share of the load, in practice once the thread engagement as reached about 1.5 to 2 times the bolt diameter there is little to be gained after that.

Another way to increase the joint strength might be to fit a helicoil insert but this would only work if it's the female thread that's failing.

“Do not worry about your problems with mathematics, I assure you mine are far greater.” Albert Einstein

tbuelna & desertfox etc.

Just FYI looks like the OP has been edited but the original version indicated the OP might be a student. It's an interesting enough question that I asked site mgmt to give some leeway but we should probably try to phrase our responses in a way that gets the OP to do some digging on theory etc. them self.

(Note, just my 2C doesn't reflect site management opinion or policy etc.)

Just FYI looks like the OP has been edited but the original version indicated the OP might be a student. It's an interesting enough question that I asked site mgmt to give some leeway but we should probably try to phrase our responses in a way that gets the OP to do some digging on theory etc. them self.

(Note, just my 2C doesn't reflect site management opinion or policy etc.)

Posting guidelines faq731-376 (probably not aimed specifically at you)

What is Engineering anyway: faq1088-1484

What is Engineering anyway: faq1088-1484

- Thread starter

- #8

- Status

- Not open for further replies.

Similar threads

- Locked

- Question

- Replies

- 4

- Views

- 1K

- Replies

- 23

- Views

- 6K

- Locked

- Question

- Replies

- 6

- Views

- 3K

- Question

- Replies

- 37

- Views

- 27K

- Locked

- Question

- Replies

- 10

- Views

- 1K