Inchtain

Petroleum

- Feb 21, 2021

- 130

Hello,

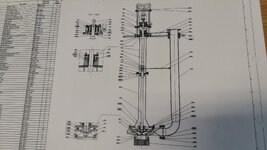

We have two vertical pump installed (one is stand-by) at an API Separator to transfer the recovered crude oil back to the production separators, where the suction section is submersed in the oil.

Few days ago, when the operator was ordered to switch off the working pump and start up the other, he noticed some vapors coming from the part below the liquid, just after pressing the ON button. He immediately turned the pump off and reported the situation to HSEQ.

I know that it is much more reasonable if smokes seen at the pump motor. So, can anyone tell the possible causes of such situation, before pulling out the pump for general check and maintenance?

Bearing in mind that the pump was working smooth before this issue.

Technical Date:

Max. crude oil temp: 80 degrees Celsius

Ambient Temperature Range: 0 to 55 degrees Celsius

Pump is certified for sour, corrosive and ATEX environment

Flanged mounting

API seals

Pump max. flowrate: 108 m3/hr

Pump Max. differential Pressure: 24 bar

Pump max fluid temperature: 130 degrees Celcius

Pump min fluid temperature: -12 degrees Celcius

Pump Ambient Temperature range: -40 to +55 Degrees Celcius

Pump Max speed: 310 rpm

Pump approximate dimensions LXWXH: 8.3X1X1.1 meters

Main Connections: Suction 8"/Discharge 8"

Pump Max fluid viscosity: 10000 cP

Thanks,

We have two vertical pump installed (one is stand-by) at an API Separator to transfer the recovered crude oil back to the production separators, where the suction section is submersed in the oil.

Few days ago, when the operator was ordered to switch off the working pump and start up the other, he noticed some vapors coming from the part below the liquid, just after pressing the ON button. He immediately turned the pump off and reported the situation to HSEQ.

I know that it is much more reasonable if smokes seen at the pump motor. So, can anyone tell the possible causes of such situation, before pulling out the pump for general check and maintenance?

Bearing in mind that the pump was working smooth before this issue.

Technical Date:

Max. crude oil temp: 80 degrees Celsius

Ambient Temperature Range: 0 to 55 degrees Celsius

Pump is certified for sour, corrosive and ATEX environment

Flanged mounting

API seals

Pump max. flowrate: 108 m3/hr

Pump Max. differential Pressure: 24 bar

Pump max fluid temperature: 130 degrees Celcius

Pump min fluid temperature: -12 degrees Celcius

Pump Ambient Temperature range: -40 to +55 Degrees Celcius

Pump Max speed: 310 rpm

Pump approximate dimensions LXWXH: 8.3X1X1.1 meters

Main Connections: Suction 8"/Discharge 8"

Pump Max fluid viscosity: 10000 cP

Thanks,