A vendor is using a continuous gas furnace for 316L stainless steel pipe solution annealing. The rolling speed is set to allow 6 minutes per mm (e.g. for 16 mm thick, the travel time is 96 minutes) including heating and soaking period in the continuous furnace. This is followed top/bottom by water spray for cooling/quenching. Distance between the furnace end and the water spray is about 1.5ft (500 mm).

I am worried about the temperature gradient between the furnace end and the water spray with consideration to the slow travel speed.

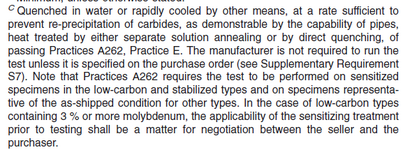

Now, Is ASTM A262, Practice E sufficient to ensure solution annealing of 316L stainless steel?

what if it was duplex SS ?

I am worried about the temperature gradient between the furnace end and the water spray with consideration to the slow travel speed.

Now, Is ASTM A262, Practice E sufficient to ensure solution annealing of 316L stainless steel?

what if it was duplex SS ?