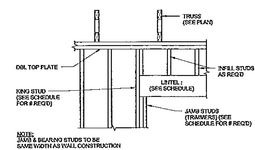

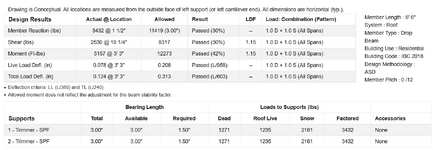

I have some questions about king and jack (trimmer) studs. Some of its generic but also pertains to 9.23.10.6 of the NBCC (National Building Code of Canada). I size headers/lintels primarily using iStruct taking into account loads from floors, roofs, decks, girders...everything. Based on these loads I get a header sized (i.e. 2-ply 2x10 SPF#2) with a bearing requirement. This number is in inches so I always round up in increments of 1.5" to match lumber size. Assuming my calculations show I only need 1.5" of bearing, I need as per the code:

A lot of my designs are in high snow load areas (BC Interior, ski hill chalets for the rich and not so famous). If I have a 4' header, 2ply 2x10 with bearing requirements of 4.5", it is my assumption that this directly translates into 3 jack studs. Do I need more than 1 king stud? Is there a rule of thumb or table for this. Let's say I have a 13' header, 3 ply 9.5" LVL requiring 6" bearings, again I assume that this means 4 jack studs each side. What about the king studs? Does which floor of the building play into this?

Up until now this was pretty irrelevant to me as the walls were out of my scope. I am trying to get up to speed on pre-fabricated wall panels and this is one of the first questions I had.

I tried finding answers from The Mighty Google but didn't really get the answers I need. Any guidance, resource, etc. is appreciated.

Thanks.

- For less than 3 m (~9-10") span I need 1 jack stud and 1 king stud.

- For greater than 3 m I need 2 jack studs and 1 king stud regardless if my calculations work at 1.5" of bearing.

A lot of my designs are in high snow load areas (BC Interior, ski hill chalets for the rich and not so famous). If I have a 4' header, 2ply 2x10 with bearing requirements of 4.5", it is my assumption that this directly translates into 3 jack studs. Do I need more than 1 king stud? Is there a rule of thumb or table for this. Let's say I have a 13' header, 3 ply 9.5" LVL requiring 6" bearings, again I assume that this means 4 jack studs each side. What about the king studs? Does which floor of the building play into this?

Up until now this was pretty irrelevant to me as the walls were out of my scope. I am trying to get up to speed on pre-fabricated wall panels and this is one of the first questions I had.

I tried finding answers from The Mighty Google but didn't really get the answers I need. Any guidance, resource, etc. is appreciated.

Thanks.