jayakumaran

Marine/Ocean

- Nov 27, 2024

- 18

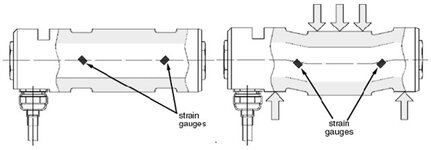

I want to know how these strain gauges are kept inside the load pin?, look image for reference.

I know using adhesive glue these guages are fitted but my question is inside? or outside(surface of the load pin grooves)?

if inside, how these are kept?. if outside, how these can be sealed?, please someone give me a solution,

or any other better place to fit these gauges please suggest me,Thanks in advance.