Datpt

Structural

- Sep 29, 2023

- 12

Hi everyone,

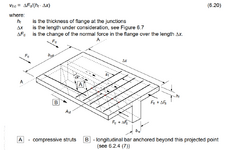

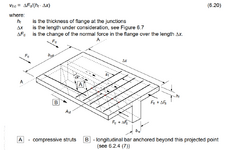

Recently, I’ve been designing a lot of ribbed slabs and have a question about the calculation of transverse reinforcement for resisting longitudinal shear between the web and the flange of T-beams.

The general approach for this is clear: we use the strut-and-tie model, where transverse reinforcements are in tension.

However, Eurocode 2 (2002) states that when there is also transverse bending (which I understand as the slab’s bending moment about the beam’s longitudinal axis), the reinforcement should be calculated as follows:

"In the case of combined shear between the flange and the web, and transverse bending, the area of steel should be the greater of that given by Expression (6.21), or half that given by Expression (6.21) plus that required for transverse bending."

Expression (6.21) provides the area of transverse reinforcement needed for longitudinal shear. Based on my understanding, this means we should detail the reinforcement as:

Max(rebar for longitudinal shear,0.5×rebar for longitudinal shear+rebar for transverse bending)

Meanwhile, the 2023 version of Eurocode states:

"If reinforcement is placed only in the tension zone due to transverse bending, the area of steel should be the greater of that required for bending and that required for shear."

This would translate to:

Max(rebar for longitudinal shear,rebar for transverse bending)

On the other hand, the FIB Model Code suggests:

"Unless a more detailed analysis is undertaken, reinforcement for introducing forces into the flanges is to be superimposed on that required for transverse bending."

This implies: rebar for longitudinal shear+rebar for transverse bending

What do you all think about these approaches? I’d greatly appreciate hearing your opinions and insights!

Recently, I’ve been designing a lot of ribbed slabs and have a question about the calculation of transverse reinforcement for resisting longitudinal shear between the web and the flange of T-beams.

The general approach for this is clear: we use the strut-and-tie model, where transverse reinforcements are in tension.

However, Eurocode 2 (2002) states that when there is also transverse bending (which I understand as the slab’s bending moment about the beam’s longitudinal axis), the reinforcement should be calculated as follows:

"In the case of combined shear between the flange and the web, and transverse bending, the area of steel should be the greater of that given by Expression (6.21), or half that given by Expression (6.21) plus that required for transverse bending."

Expression (6.21) provides the area of transverse reinforcement needed for longitudinal shear. Based on my understanding, this means we should detail the reinforcement as:

Max(rebar for longitudinal shear,0.5×rebar for longitudinal shear+rebar for transverse bending)

Meanwhile, the 2023 version of Eurocode states:

"If reinforcement is placed only in the tension zone due to transverse bending, the area of steel should be the greater of that required for bending and that required for shear."

This would translate to:

Max(rebar for longitudinal shear,rebar for transverse bending)

On the other hand, the FIB Model Code suggests:

"Unless a more detailed analysis is undertaken, reinforcement for introducing forces into the flanges is to be superimposed on that required for transverse bending."

This implies: rebar for longitudinal shear+rebar for transverse bending

In summary:

- Eurocode 2 (2002):

Max(rebar for longitudinal shear,0.5×rebar for longitudinal shear+rebar for transverse bending) - Eurocode (2023):

Max(rebar for longitudinal shear,rebar for transverse bending) - FIB Model Code:

rebar for longitudinal shear+rebar for transverse bending

What do you all think about these approaches? I’d greatly appreciate hearing your opinions and insights!