EfficientPuppy

Structural

- May 10, 2024

- 17

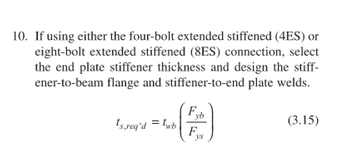

We are looking into doing an angle end plate splice. It feels unconventional to me, but I can't think of a logical reason why it wouldn't work so I am moving forward with it. The problem is that I can not think of a way to design all of it. Gusset/stiffener plate will be added to the angle to effectively make the profile at the end plate into a + shape with four bolts added, one at each corner of the end plate. I am feeling fairly confident in using the prying action approach in AISC steel manual to size the thickness of the end plate. My question is if there is any way to design the gusset/stiffener plates other than some rules of thumb. Like the thickness of the gusset ought to match the angle leg thickness so I don't get some eccentricities due to a difference in stiffness, and the length of the gussets down the angle I was going to set to a taper of 2:1 because, I don't know, it feels right...? I guess I don't have any sort of justification for that and I guess that is what I am looking for some help on.