dogbural

Aerospace

- Jan 25, 2009

- 74

Hi,

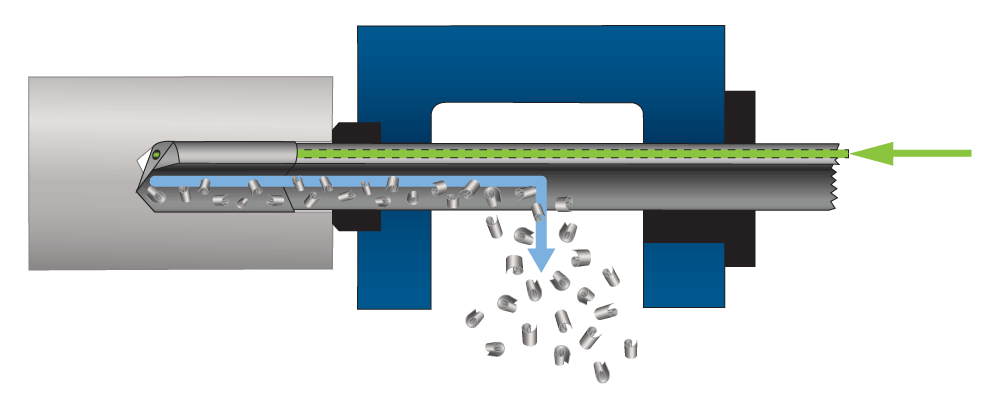

Our supplier have to machine a long tube (OD: 55, ID: 53, Length 380mm) from thicker tube (OD 58, ID 50)

They use a CNC lathe machine and when they machine ID, they machine from both ends - machine one end and flip it for the other end.

It is apparent to see the a little bumpy line at the mid point.

Drawing requirement is that total runout of ID should be 100 micron in reference to OD surface.

What would be best way to machine such a long tube?

Our supplier have to machine a long tube (OD: 55, ID: 53, Length 380mm) from thicker tube (OD 58, ID 50)

They use a CNC lathe machine and when they machine ID, they machine from both ends - machine one end and flip it for the other end.

It is apparent to see the a little bumpy line at the mid point.

Drawing requirement is that total runout of ID should be 100 micron in reference to OD surface.

What would be best way to machine such a long tube?