FrancoisY

Mechanical

- Nov 10, 2023

- 20

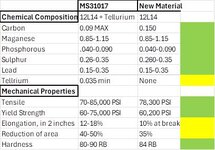

I would like guidance on this material change. The new material (12L14) is the same but without Tellurium. Tellurium improves machinability and lead, but i've discovered it didn't matter for my sake. The material properties are similar, except the “Reduction in Area.” I am not too concern with chemical composition except carbon unless mistaken. It does state that original Carbon is 0.09MAX. Maybe the carbon can play a big role?

Reduction in area - Technically states the higher the % the more ductile it is and performed better; likely the ability to deform without breaking.

Original material ranges from 40% - 50%. The new material has 35% meaning it will be less ductile than the our original material by 5%. Everything else relating physical and chemical properties are the same. Do you all think with this 5% reduction, it would be a HUGE deal? I know if a product is more than 50%, it would be an issue because it would be too ductile.

Reduction in area - Technically states the higher the % the more ductile it is and performed better; likely the ability to deform without breaking.

Original material ranges from 40% - 50%. The new material has 35% meaning it will be less ductile than the our original material by 5%. Everything else relating physical and chemical properties are the same. Do you all think with this 5% reduction, it would be a HUGE deal? I know if a product is more than 50%, it would be an issue because it would be too ductile.