HDStructural

Structural

Hello All,

I am working on a project where a PEMB is being modified due to future change of use causing the loads to increase. The owner knows that there is next to no additional capacity in their building and that costly reinforcement will be required to beef up the whole structure. Thankfully, the foundations are good for the increased loads.

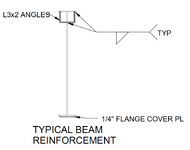

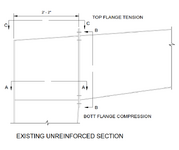

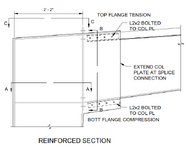

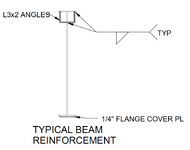

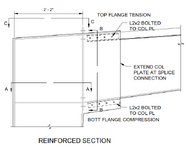

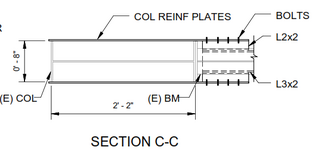

For the roof beams, I am planning to use a cover plate on the bottom flange and angles at the top flange to reinforce the structure.

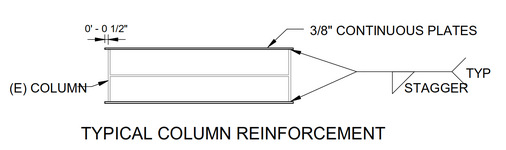

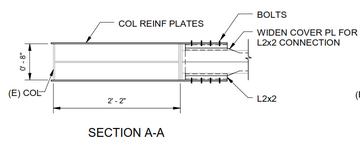

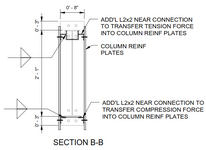

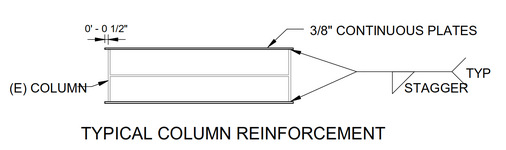

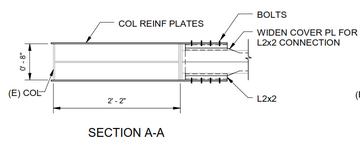

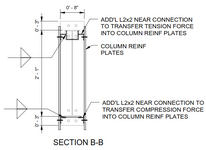

I have designed side plates for the column reinforcement, essentially turning the I shape columns into box sections. I considered reinforcing the column similar to the beams, but turning the column into a box section simplifies a lot of connections and gets rid of many reinforcing plate splices.

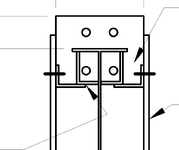

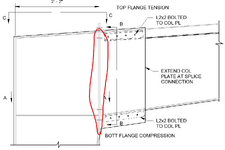

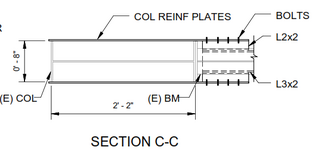

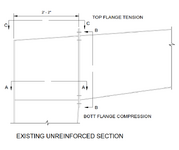

I am having difficulty coming up with a simple connection at the beam to column splice connection. I am planning to design reinforcement at the splice connection just for the new loads on the structure, since the original detail is good for the original loads. The existing splice connection is a bolted end plate connection.

My idea is to extend the column reinforcement plates out beyond the splice so that the beam reinforcement can be connected directly to the column reinforcement. I would use angles to connect the main beam reinforcement to the column reinforcement. See below.

Does this seem feasible to you? Any ideas for improving the detail?

I am working on a project where a PEMB is being modified due to future change of use causing the loads to increase. The owner knows that there is next to no additional capacity in their building and that costly reinforcement will be required to beef up the whole structure. Thankfully, the foundations are good for the increased loads.

For the roof beams, I am planning to use a cover plate on the bottom flange and angles at the top flange to reinforce the structure.

I have designed side plates for the column reinforcement, essentially turning the I shape columns into box sections. I considered reinforcing the column similar to the beams, but turning the column into a box section simplifies a lot of connections and gets rid of many reinforcing plate splices.

I am having difficulty coming up with a simple connection at the beam to column splice connection. I am planning to design reinforcement at the splice connection just for the new loads on the structure, since the original detail is good for the original loads. The existing splice connection is a bolted end plate connection.

My idea is to extend the column reinforcement plates out beyond the splice so that the beam reinforcement can be connected directly to the column reinforcement. I would use angles to connect the main beam reinforcement to the column reinforcement. See below.

Does this seem feasible to you? Any ideas for improving the detail?