Has anyone ever worked with plastic as a structural material? It seems to me that the industry accepts it in a few applications like exterior decking or roofs for greenhouses. Or in composite applications such as adding fibres to concrete. Though it seems like there is a cut off line where the structural member is not a deck and fully plastic (no beams, columns). Why haven't we made small beams or studs out of recycled polypropylene?

A couple that are out on the market below:

thruflow.com

thruflow.com

plasticlumberyard.com

plasticlumberyard.com

jdcomposites.ca

jdcomposites.ca

A couple that are out on the market below:

ThruFlow – Premium Decking Solutions

INTRODUCING LEGACY XP 2'X4' PANELS Featuring a 24" span! GO WITH THE FLOW The open architecture of ThruFlow™ allows your dock to fight the power of water's surg

Shop 5/4 in x 6 in Structural Plastic Lumber

Discover the durability and versatility of our 5/4 in x 6 in HDPE board. Resistant to weather, rot, and fading, it’s perfect for decking, docks, and outdoor projects.

plasticlumberyard.com

plasticlumberyard.com

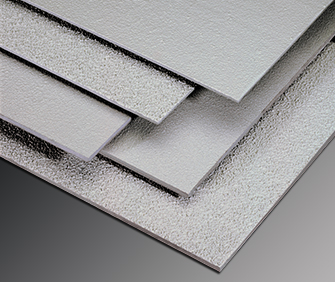

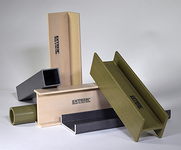

JD Composites - JD Composites

We have a vision of a greener future, where we help create a new line of architectural structures using 100% recycled PET plastic bottles.

jdcomposites.ca

jdcomposites.ca