I have a few questions about plate washers that AS4100/AS5100.6 require for oversize or slotted holes. I want to make sure I have this right.

Taking the case of an M20 bolt as an example, it is clear from the code that anything other than a standard 22 diameter hole would count as oversize or slotted and therefore would require a hardened or plate washer that covers the entire extent of the hole plus an overlap of half the hole diameter. It is not clearly stated but I presume the bolt needs to be considered in its extreme position in the hole, rather than central.

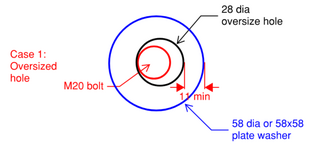

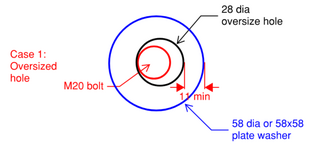

The below sketch is showing a 28 diameter oversize hole, which is the largest allowed for an M20 bolt - requiring a 58 diameter or 58x58 square washer:

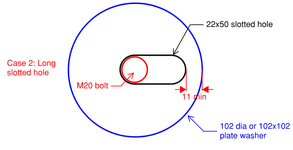

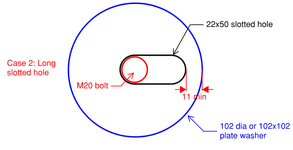

So far that's not too bad, but for a long slotted hole (22x50 in this case is the largest allowed), the plate washers start getting very unwieldy (102 diameter or 102x102 square in this case):

My question is, are people actually specifying and installing such large plate washers? Is it allowed to instead consider the bolt in its central location or does it need to be assumed right at the edge? I'm sure I have come across previous designs using oversize or slotted holes where plate washers were not specified.

Just curious how this is handled by others?

Thanks in advance

Taking the case of an M20 bolt as an example, it is clear from the code that anything other than a standard 22 diameter hole would count as oversize or slotted and therefore would require a hardened or plate washer that covers the entire extent of the hole plus an overlap of half the hole diameter. It is not clearly stated but I presume the bolt needs to be considered in its extreme position in the hole, rather than central.

The below sketch is showing a 28 diameter oversize hole, which is the largest allowed for an M20 bolt - requiring a 58 diameter or 58x58 square washer:

So far that's not too bad, but for a long slotted hole (22x50 in this case is the largest allowed), the plate washers start getting very unwieldy (102 diameter or 102x102 square in this case):

My question is, are people actually specifying and installing such large plate washers? Is it allowed to instead consider the bolt in its central location or does it need to be assumed right at the edge? I'm sure I have come across previous designs using oversize or slotted holes where plate washers were not specified.

Just curious how this is handled by others?

Thanks in advance

Last edited: