MPSU

Automotive

- Aug 26, 2024

- 23

Hey everyone,

I'm working on a new drawing and came across something confusing.

I've attached pictures for reference. Would love to hear your thoughts!

I'm working on a new drawing and came across something confusing.

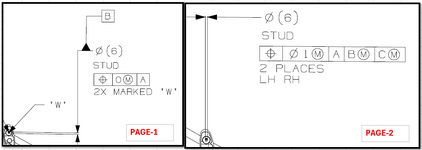

- Datum A is a plane.

- Datum B is a stud, which has a positional tolerance on one side (without the Ø symbol).

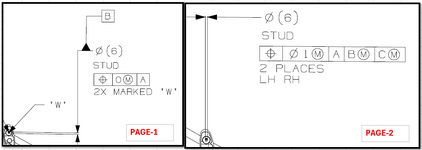

- On the next page of the drawing, the same stud is referenced again, but this time with a positional tolerance relative to A, B, and C datums.

I've attached pictures for reference. Would love to hear your thoughts!