Hi All,

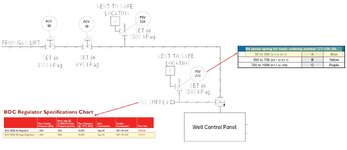

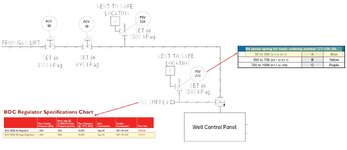

I am trying to size a PSV (PSV172) for a Nitrogen Supply Line to Well Control Panel as per attached file.

The PSV is installed on the N2 Supply Line with a set pressure of 1,380 kPag and Vent to Safe Location.

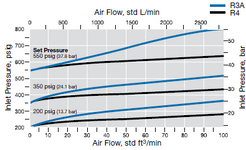

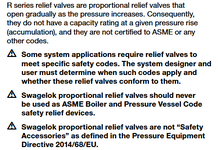

I have some information of the Nitrogen Regulator (BOC Regulator 8000) with it's specification and the type of installed PSV (Swagelok R4 Series).

My question is:

1. Is this PSV only protect the overpressure from Nitrogen Supply? or it protect also from Gas List Control Valve Failure Scenario? Which one is valid scenario?

2. How can calculate the rated flow of the PSV for a scenario of Nitrogen Regulator Failure (from BOC Regulator spec sheet, the flow rate at 21,000 kPag is 1,086 L/min)?

Please see the attached file of the schematic drawing with additional information of BOC Regulator and Swagelok PSV.

Much thanks

I am trying to size a PSV (PSV172) for a Nitrogen Supply Line to Well Control Panel as per attached file.

The PSV is installed on the N2 Supply Line with a set pressure of 1,380 kPag and Vent to Safe Location.

I have some information of the Nitrogen Regulator (BOC Regulator 8000) with it's specification and the type of installed PSV (Swagelok R4 Series).

My question is:

1. Is this PSV only protect the overpressure from Nitrogen Supply? or it protect also from Gas List Control Valve Failure Scenario? Which one is valid scenario?

2. How can calculate the rated flow of the PSV for a scenario of Nitrogen Regulator Failure (from BOC Regulator spec sheet, the flow rate at 21,000 kPag is 1,086 L/min)?

Please see the attached file of the schematic drawing with additional information of BOC Regulator and Swagelok PSV.

Much thanks