BacBac

Structural

- Aug 11, 2024

- 21

Hi All,

Structural engineer from Australia here.

I'm currently working on the construction phase of a project where the floor system is PT suspended slab, and our office is detailing the PT slab.

The typical tendon length on this project is >24m.

The design was completed using popular software in Australia which are RAPT and RAM Concept, with its default tendons anchorage loss values and default initial jacking stress (85% minimum breaking load).

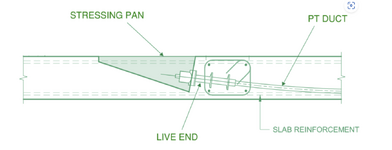

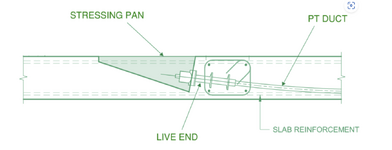

Due to site constraint, most of the PT anchorage are done by pan stressing (refer snapshot below).

However, when the elongation stressing record were sent by the contractor, we noticed that the actual elongation on these pans are much lower (up to approx. 15-20%) than the theoretical elongation from RAPT or RAM Concept.

We requested the PT subcontractor to restress those tendons, however, what they did was to apply a jacking force >85% of the minimum breaking load of the tendons to achieve longer elongation.

I'm not too sure if this is the correct approach as most of the pans tendons have low elongation and the risk of tendons snapping.

Could you advise on the typical approach in this situation?

Any help would be greatly appreciated.

Structural engineer from Australia here.

I'm currently working on the construction phase of a project where the floor system is PT suspended slab, and our office is detailing the PT slab.

The typical tendon length on this project is >24m.

The design was completed using popular software in Australia which are RAPT and RAM Concept, with its default tendons anchorage loss values and default initial jacking stress (85% minimum breaking load).

Due to site constraint, most of the PT anchorage are done by pan stressing (refer snapshot below).

However, when the elongation stressing record were sent by the contractor, we noticed that the actual elongation on these pans are much lower (up to approx. 15-20%) than the theoretical elongation from RAPT or RAM Concept.

We requested the PT subcontractor to restress those tendons, however, what they did was to apply a jacking force >85% of the minimum breaking load of the tendons to achieve longer elongation.

I'm not too sure if this is the correct approach as most of the pans tendons have low elongation and the risk of tendons snapping.

Could you advise on the typical approach in this situation?

Any help would be greatly appreciated.